TB 9-4940-548-30

4. Installation--Continued

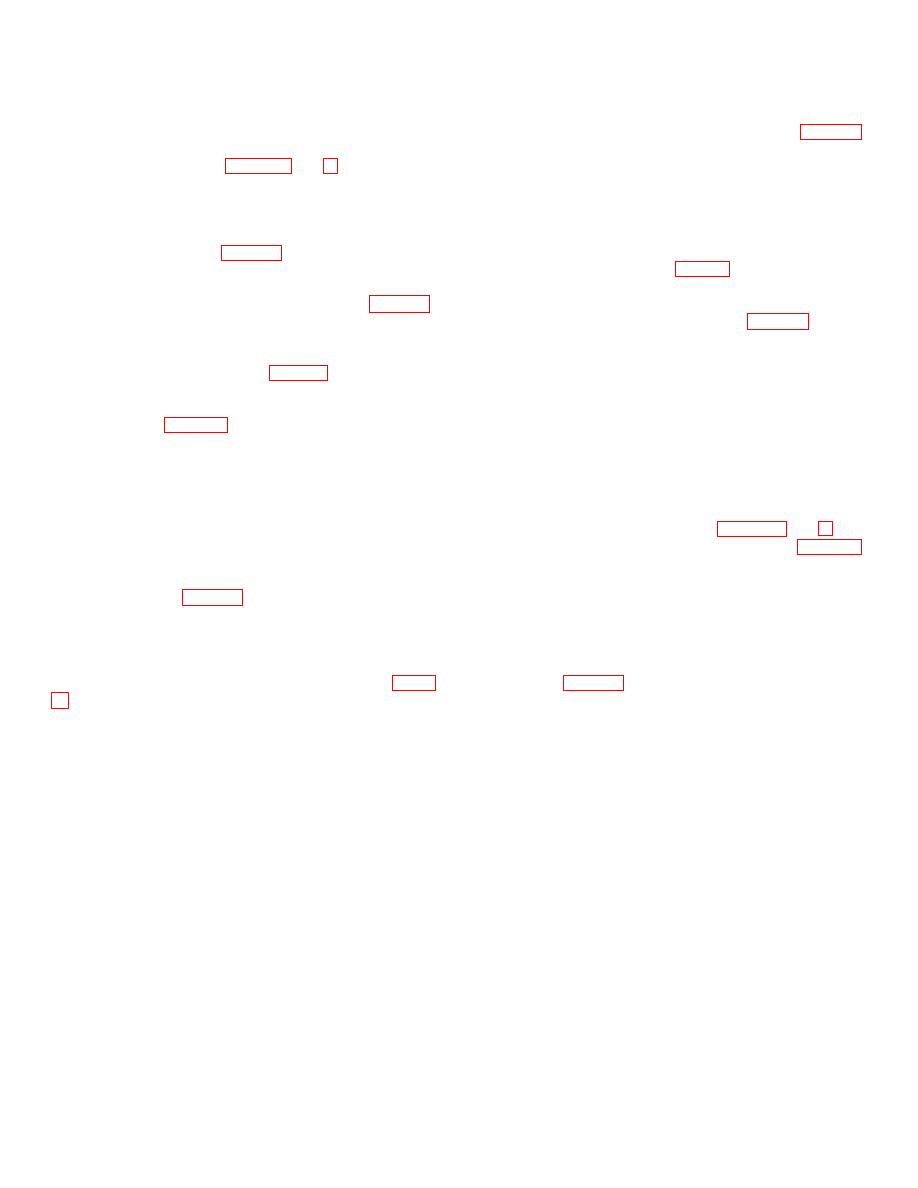

e. Position portable drill stand (5130-00-263-8663)

in accordance with dimensions specified in figure 2.

a. Mark and drill ten 0.25-in. diameter holes in van

Using portable drill stand base as a template, mark and

drill three 0.34-in. diameter holes through tabletop.

nuts. Install ten #10 blind rivet nuts (MS27130-A27).

Secure portable drill stand to work table with three 5/16-

x 3-1/4-in. machine bolts (MS90725-45), three 5/16-in.

b. Install two strap loops (MS51939-3) with four

flat washers (MS27183-11), three 5/16-in. lockwashers

#10 x 1-in. countersunk head machine screws

(MS35338-45), and three 5/16-in. hex nuts (MS51967-

(MS35190-275). Refer to figure 4 for location.

5). Install portable electric drill (5130-00-889-9000) on

portable drill stand. Refer to figure 3.

c. Position four work tables (4910-00-543-7771

and 4910-00-543-7772) in van as shown in figure 2.

f. Locate reciprocating compressor unit (4310-00-

Mark and drill twelve 0.34-in. diameter holes through

542-4111) on tabletop as shown in figure 2. Using

work tablelegs. Using holes in work table legs as

reciprocating compressor unit base as template, mark

templates, mark and drill twelve 0.23-in. diameter pilot

and drill four 0.25-in. diameter holes through tabletop.

holes in floor in accordance with figure 5. After mounting

Secure reciprocating compressor unit to tabletop using

work tables mark and drill sixteen 0.34-in. diameter

four #10 x 3-in. pan head machine screws (MS35206-

holes through furnished wall-mounted angle irons in

275), eight #10 flat washers (MS27183-42), four #10

accordance with figure 2. Reposition work tables under

lockwashers (MS35338-43), and four #10 hex nuts

angle irons so that floor drilled holes are alined with

(MS35649-202).

holes in work table legs. Using the holes in the angle

irons as templates, mark and drill sixteen 0.23-in.

g. Remove contents of general purpose first aid kit

diameter pilot holes into tabletops. Secure work tables

Mark and drill three 0.22-in.

to angle irons and floor using twenty-eight 5/16- x 1-1/4-

diameter holes in the back of general purpose first aid

in. hex head lag bolts (MS16992-521) and twenty-eight

5/16-in. lockwashers (MS35338-45).

installed blind rivet nuts in accordance with figure 3.

Secure general purpose first aid kit to wall of van using

d. Position two filing cabinets (7110-00-634-2860)

three #10 x 1-in. countersunk head machine screws

in accordance with figure 2. Mark and drill four 0.34-in.

(MS35190-275). Reinstall contents in general purpose

diameter holes in each filing cabinet bottom plate.

first aid kit.

Locate at the four corners, allowing minimum required

clearance for 5/16-in. hex head lag bolts. Using filing

h. Position utility grinding machine (3415-00-517-

cabinets as templates, mark and drill eight 0.23-in.

7754) on tabletop in accordance with dimensions

diameter pilot holes in van floor in accordance with figure

specified in figure 2. Using utility grinding machine base

as template, mark and drill three 0.34-in. diameter holes

1-1/4-in. hex head lag bolts (MS16992-521) and eight

through tabletop. Secure utility grinding machine to work

5/16-in. lockwashers (MS35338-45).

table with three 5/16- x 2-3/4-in. hex head

7