f.

With air compressor unit operating pull ENGINE

THROTTLE CONTROL to the full out position and lock in

place.

g.

Push

ENGINE

THROTTLE

CONTROL

completely in to stop.

h.

If engine does not stop, loosen wire stop (13,

Figure 8-30) and adjust throttle lever until engine stops.

Without disturbing setting of throttle lever, tighten wire

stop (13).

i.

Repeat steps a through e. Pull engine

THROTTLE CONTROL to the full out position and lock

by turning handle in clockwise direction. The engine

should operate at 2150 i 50 rpm (2150 + 50 r/min).

WARNING

Make certain all control valves on control panel are

closed.

j.

Engage clutch by pushing CLUTCH operating rod

towards panel. Place COMPRESSOR UNLOADER

switch to LOAD position to pressurize receiver.

k.

Observe Service Pressure gauge (4, Figure 4-2) indi-

cation. With air compressor unit operating under normal

conditions, the compressor unit should unload at a maxi-

mum pressure of 3400 psig (23, 426 kPa). The air

compressor unit should load at a minimum pressure of

3100 psig (21, 359 kPa). If air compressor loads or

unloads

at

an

in-correct

pressure,

refer

to

TROUBLESHOOTING (Section V).

l.

Open the SERVICE HOSE BLEED valve, MECH-

ANICAL FILTER DRAIN valve and DEHYDRATOR

BLEED VALVE. Observe the COMPRESSOR OUTPUT

and SERVICE PRESSURE pressure gauges.

m. Place the COMPRESSOR UNLOADER SWITCH

(16, Figure 4-2) to the UNLOAD position.

n.

Disengage clutch by pulling CLUTCH operating rod

away from control panel. Push ENGINE THROTTLE

CONTROL in to the idle position.

o.

Allow engine to run without a load at idle speed for

approximately five (5) minutes.

p.

Push ENGINE THROTTLE CONTROL completely

in. Turn MASTER SWITCH 450 ccw.

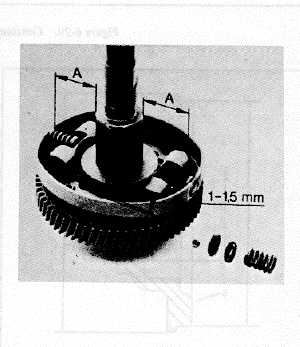

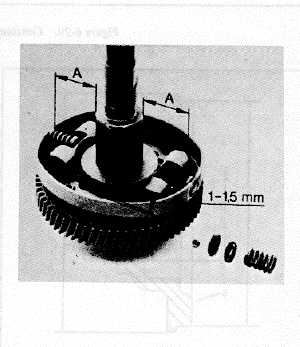

Figure 6-28. Spring Plate to Camshaft Adjustment.

6-73