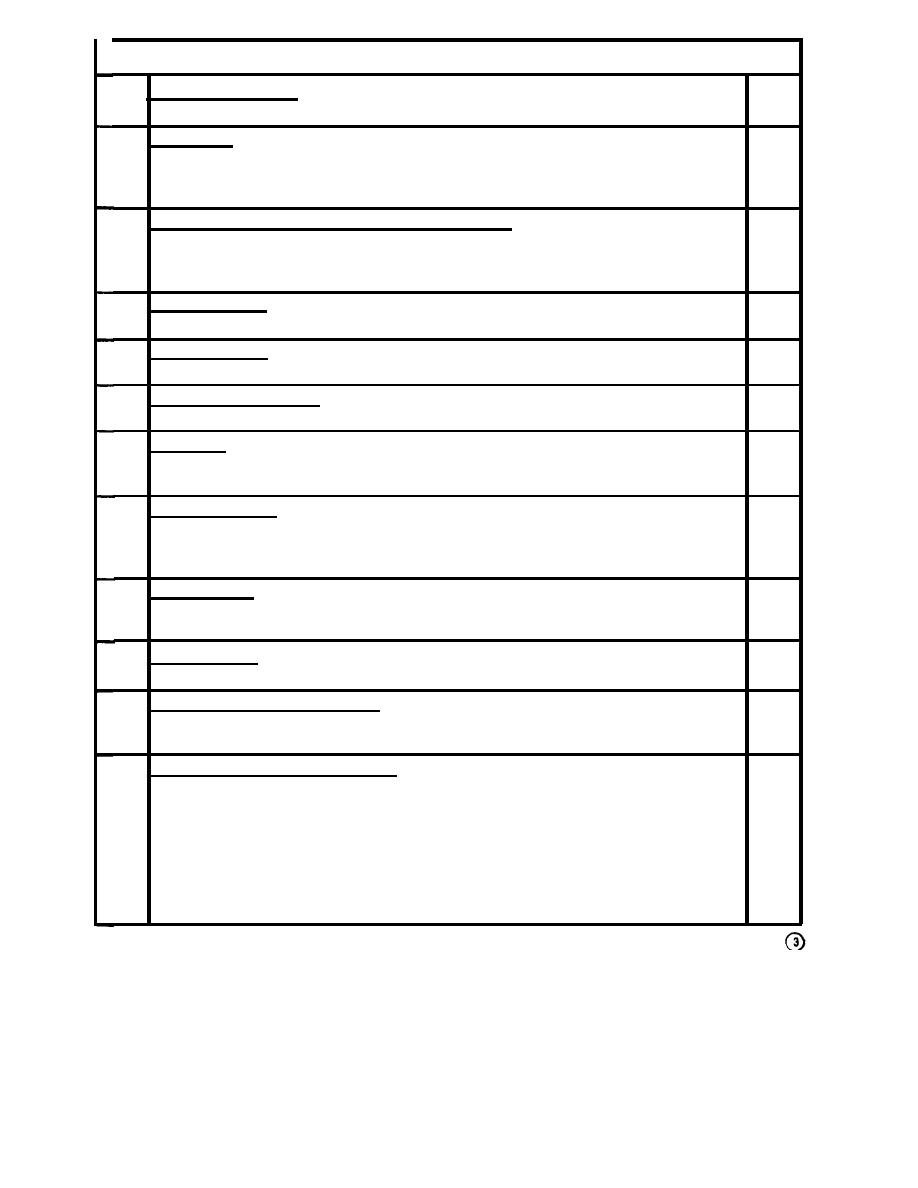

PAR REF

ITEM

FIRE EXTINGUISHER. Inspect for broken seal. Inspect for full charge by

8

shaking for sound or weight. Reference TM9-8030, par.62.

19

BATTERIES. Tighten loose cables and mountings. Remove corrosion. Fill to

3/8 inch above the plates. Clean venthole in filler cap before installing.

In freezing weather run engine minimum of 1 hour after adding water. Replace

a cracked or leaking battery. Reference TM9-8030, par. 167.

20

TRANSMISSION, TRANSFER CASE, AND DIFFERENTIALS. Add oil as indicated by

filler plugs. Reference current L.O.9-8030. Check for oil leaks. Tighten

loose mountings. Clean dirty vents. Reference TM9-8030, pars. 194,198,208,

211, and 212.

85

21

ELECTRIC MOTOR. Tighten loose mountings and electrical connections. Replace

a worn or damaged electric motor.

85

22

AIR COMPRESSOR. Tighten loose mounting and connections. Replace or repair a

worn or damaged air compressor.

37

23

COMPRESSOR FILTER PAD. Clean a dirty filter pad. Replace a defective filter

pad.

24

FUEL TANK. Add fuel as required. Tighten loose mounting. Replace leaking

fuel tank. Replace defective cap gasket. Clean cap vent. Reference

TM9-8030, par. 142.

25

GROUND TERMINAL. Check for proper ground. A proper ground will consist of

a 3/4-inch-dia. hollow rod or 5/8-inch-dia. solid rod, 9 feet long. The cable

will be No. 6 AWG copper wire, bolted or clamped to the rod and attached to

the ground terminal of the generator-welder set.

26

WELDER BELTS. Proper adjustment is a deflection of 1/2 to 3/4 inch midway

74

between power takeoff pulley and welder pulley. Check for worn, frayed, or

cracked belts.

27

POWER TAKEOFF. Lubricate in 'accordance with current L.O. Tighten loose

58

mounting. Replace or repair worn or damaged power takeoff assembly.

PROPELLER SHAFTS AND U-JOINTS. Lubricate in accordance with current L09-8030.

28

Tighten loose mounting. Replace worn or damaged shafts and joints. Reference

TM9-8030, pars. 200 and 201.

Z9

14

WELDER CONTROLS AND INSTRUMENTS. Check for damaged instruments. Tighten

loose mounting. With the unit operating, check for proper operation. Normal

operating readings for instruments are as follows:

MSC 4940-200-12/21

Figure21-Continued.

TAGO 5672-.4

50