TM 9-243

TYPES AND USES

BRACE DRILL

The brace drill is made up of the following parts: head

(1), crank (2), crank handle (3), ratchet mechanism (4),

and chuck (5). The brace is used to drill holes in wood

and with a screwdriver bit, remove and install screws.

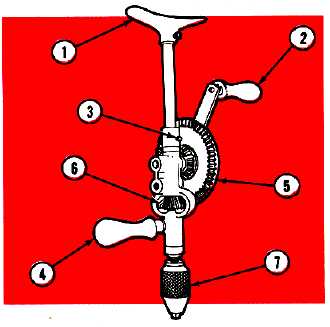

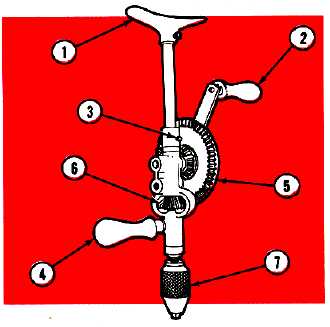

BREAST DRILL

The breast drill is made up of the following parts: breast

plate.(1), drive handle (2), speed shifter (3), side handle

(4), speed gears (5), pinion gears (6), and chuck (7).

The adjustable breast plate provides a base for the user

to lean against while using the drill. The speed shifter

provides a means of selecting high speed or low speed.

This allows the operator to start a hole at slow speed, 1:

1 ratio, preventing marring of the surface, then shifting

to high speed, 3-1/2:1 ratio, to finish drilling

the hole. To change from low speed to high speed,

move the drive handle and speed gears from the bottom

hole to the top hole. High speed position is illustrated.

Some drills have a slot instead of two holes. The side

handle provides a way to steady the drill and insure that

the bit is boring a straight hole. The speed gears

determine the speed at which the drill rotates. They are

connected through linkage to the pinion gears. The

pinion gears turn the chuck and drill. The breast drill is

used to drill holes in wood, plastic, concrete, and small

gage sheet metal.

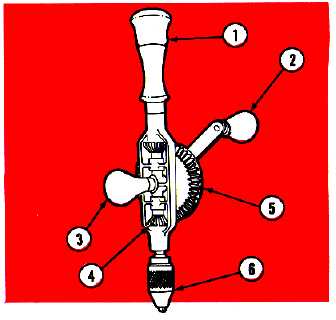

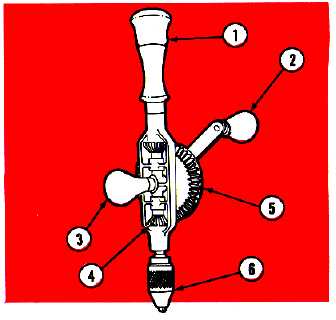

HAND DRILL

The hand drill is made up of the following parts: handle

(1), drive handle (2), side handle (3), pinion (4), gear

wheel (5) and chuck (6). The handle provides a storage

area for drill bits. The side handle may be used to

steady the drill when drilling in soft wood. The pinion

turns the chuck and drill. Through mechanical linkage,

the gear wheel transfers the driving force from the drive

handle to the chuck. Hand drills are used to drill holes

in wood and sheet metal.

23-2