TM 9-243

TYPES AND USES

A wrench is a tool specially designed to tighten or

loosen nuts, bolts, studs, and pipes. Wrenches are

forged from steel alloy to prevent breakage. There are

many different types of wrenches. Each type has its

own use. By using the proper wrench for the task to be

done, you will not break the wrench, damage the

equipment, or cause personal injury. The following

section is intended to give you information on the

different wrench types.

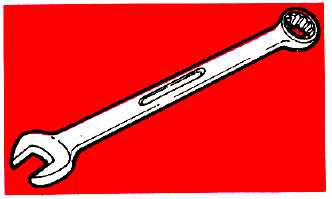

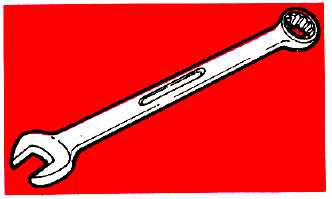

OPEN-END WRENCHES

All open-end wrenches have open jaws on one or both

ends of the wrench. Most jaw openings are offset from

the shank portion of the wrench by 15 degrees. The

wrench length is determined by the size of the jaw

opening. Some of the more common types of open-end

wrenches and their uses are listed below.

The engineer's single open-end wrench has a long

smooth shank providing the user with a better gripping

surface. It is used to reach behind or below blind

surfaces.

The engineer's double open-end wrench has different

size openings on each end. This type of an

arrangement permits a smaller number of wrenches to

complete a set. The engineer's double open-end

wrench is also used to reach behind or below blind

surfaces.

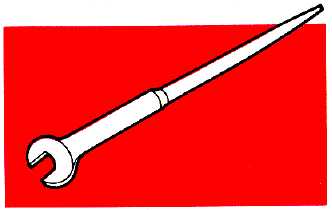

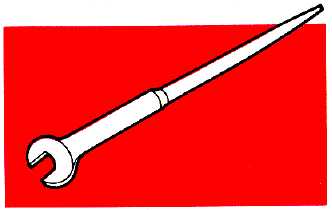

The construction wrench combines the open-end jaw

with a long tapered shank providing a wrench/alignment

punch combination. The construction wrench is used in

the building trades and on heavy objects which require

alignment before fastening.

25-2