TM 9-243

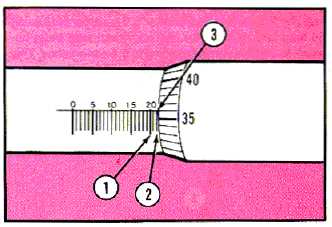

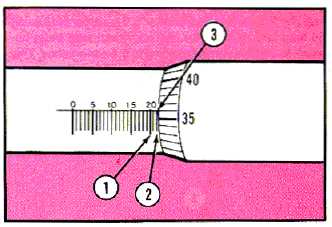

READING A METRIC MICROMETER

The same principle is applied in reading the metric

graduated micrometer, but the following changes in

graduations are used:

The pitch of the micrometer screw is 0.05 mm. One

revolution of the spindle advances or withdraws the

screw a distance equal to 0.5 mm.

The barrel (1) is graduated in millimeters from 0 to 25.

It takes two revolutions of the spindle to move the barrel

1 mm.

The thimble (2) is graduated in 50 divisions with every

fifth line being numbered.

Rotating the thimble from one graduation to the next

moves the spindle 1/50 of 0.5 mm, or 1/100 mm. Two

graduations equal 2/100 mm, and so forth.

TO READ MEASUREMENT AS SHOWN ABOVE:

Read highest figure

visible on barrel (1) ...............................20 = 20.0 mm

Number of lines visible

between the No. 20 and

thimble edge (2) ....................................... 2 = 2.0 mm

The line on the thimble

that coincides with or

has passed the

revolution or long line

in the barrel (3) .........................36 = 36/100 (.36) mm

NOTE

Remember that 1 revolution is 0.5

mm. It takes 2 revolutions to move 1

mm.

Measurement reading ...................... TOTAL 22.36 mm

CARE OF MICROMETERS

1.

Coat metal parts of all micrometers with a light

coat of oil to prevent rust.

2.

Store

micrometers

in

separate

containers

provided by manufacturer.

3.

Keep

graduations

and

markings

on

all

micrometers clean and legible.

4.

Do not drop any micrometer. Small nicks or

scratches can cause inaccurate measurements.

7-6