TM 9-243

TYPES AND USES

Levels are tools designed to prove whether a plane or

surface is in the true vertical or true horizontal. All

levels consist of a liquid-filled glass tube or tubes

supported in a frame.

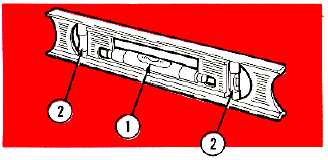

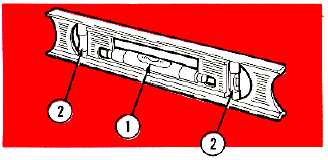

MASTER PRECISION LEVEL

The master precision level has a ground and graduated

main vial (1). The top and bottom of the level are milled

and ground to make sure both surfaces are absolutely

parallel. This level is used to determine the true

horizontal with the main vial (1). The true vertical is

determined by using the two smaller vials (2).

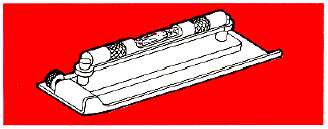

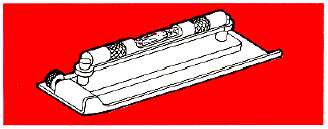

MACHINIST'S LEVEL

The machinist's level has an extra large vial, This

increases its accuracy and sensitivity. Some of these

levels have grooved bottoms which fit over pipes and

shafts. They are used in machine shops for leveling

work and equipment.

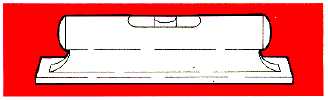

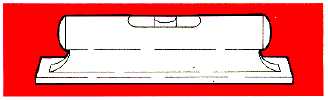

IRON BENCH LEVEL

The iron bench level is made of a special design casting

which insures its lightness, strength, and rigidity. It is

used mostly in the construction industry. It may also be

used in a machine shop.

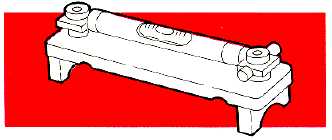

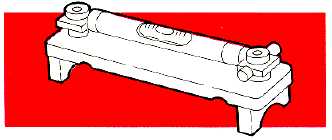

STRIDING LEVEL

The striding level is a machinist's level which is

mounted on a raised base. This level is used to span

existing cabling, piping, or similar obstructions. It is

extremely useful in a machine shop for checking the

true horizontal of the flatway on a lathe.

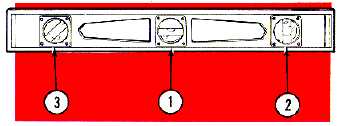

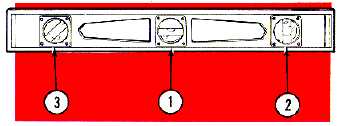

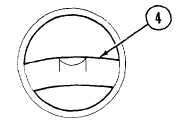

CARPENTER'S LEVEL

The carpenter's level has three vials which are mounted

horizontally (1), vertically (2), and at a 45 degree angle

(3). The carpenter's level is used in construction for

checking for true vertical, true horizontal, and 45 degree

angles.

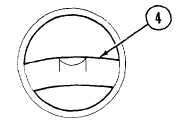

Some levels have a bent tube (4) which allows the

bubble to settle quickly.

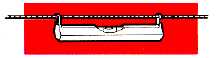

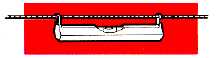

LINE LEVEL

The line level is a single vial in a metal case with a hook

on each end for hanging on a cord. It is used to check

whether two points are level, such as two points on a

floor or in an elevation. It must be used with a tightly

stretched cord.

10-2