TM 9-4940-549-14&I

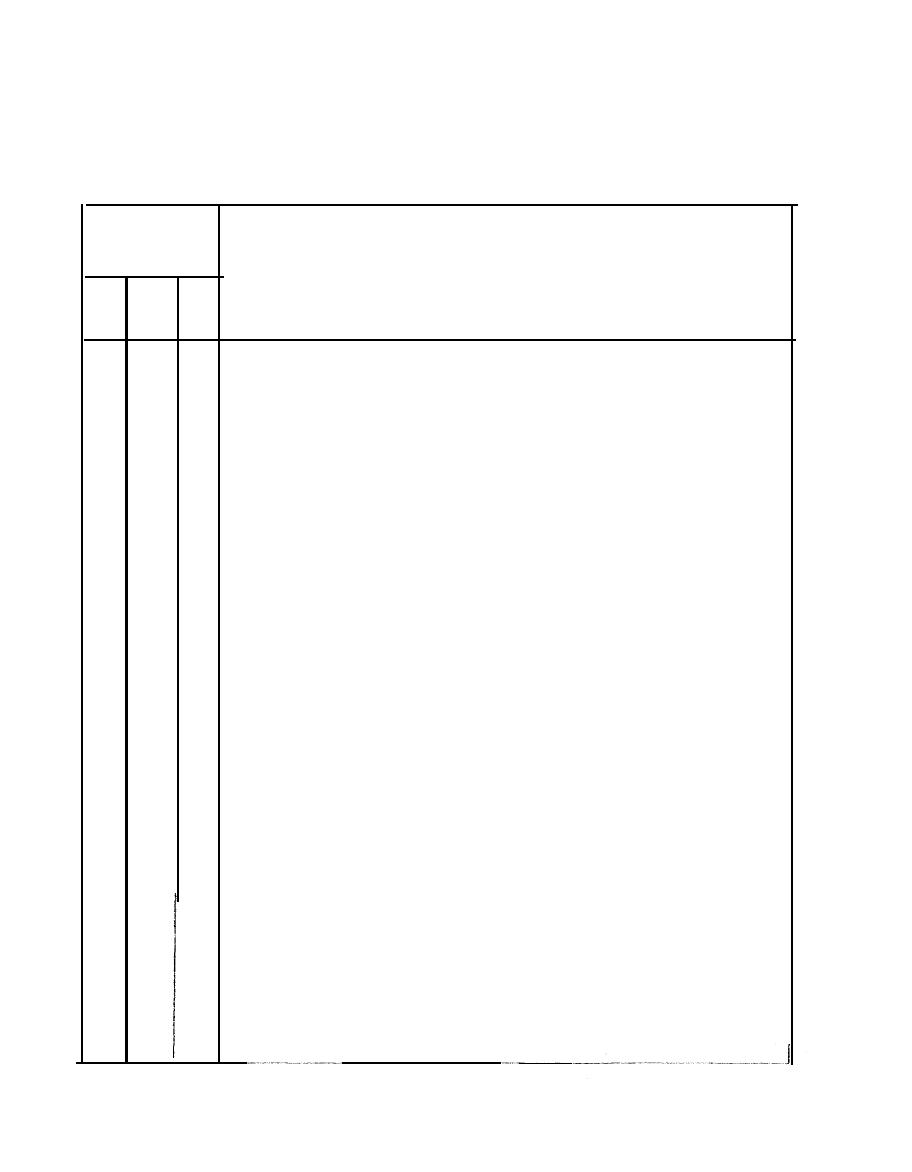

Table 3.1. Operator/Crew Preventive Maintenance Checks and Services

B-Before Operation

D-During Operation

A-After Operation

Interval

Item to be Inspected

and

Procedure

Sequence No.

B

D

A

8

Batteries

Remove corrosion. Inspect for cracks and

leaks. Tighten loose cables and mountings.

Fill to 3/8-in. above plates with distilled

water. Clean vent hole. In freezing weath-

er run engine a minimum of 1 hour after ad-

ding distilled water.

9

Hydraulic System

Add oil as required. Check for leaks.

10

17

Welder Controls and Instruments

Inspect for damage and loose mounting.

With unit operating, check for proper

operation.

Normal operating readings are as follows:

AC Voltmeter: 240-volts

Frequency Meter: 50-60 hertz

DC Voltmeter: Terminal voltage

DC Ammeter: Not to exceed 300 amps

11

18

Engine Controls and Instruments

Inspect for damage and loose mounting.

With unit operating, check for proper

operation.

Normal operating readings are as follows:

Water temperature gage: 180-195F.

Oil pressure: 40-60 psi

Battery generator indicator:

pointer to green

1,800 rpm at 60 hertz

3-3