TM 9-4940-549-14&P

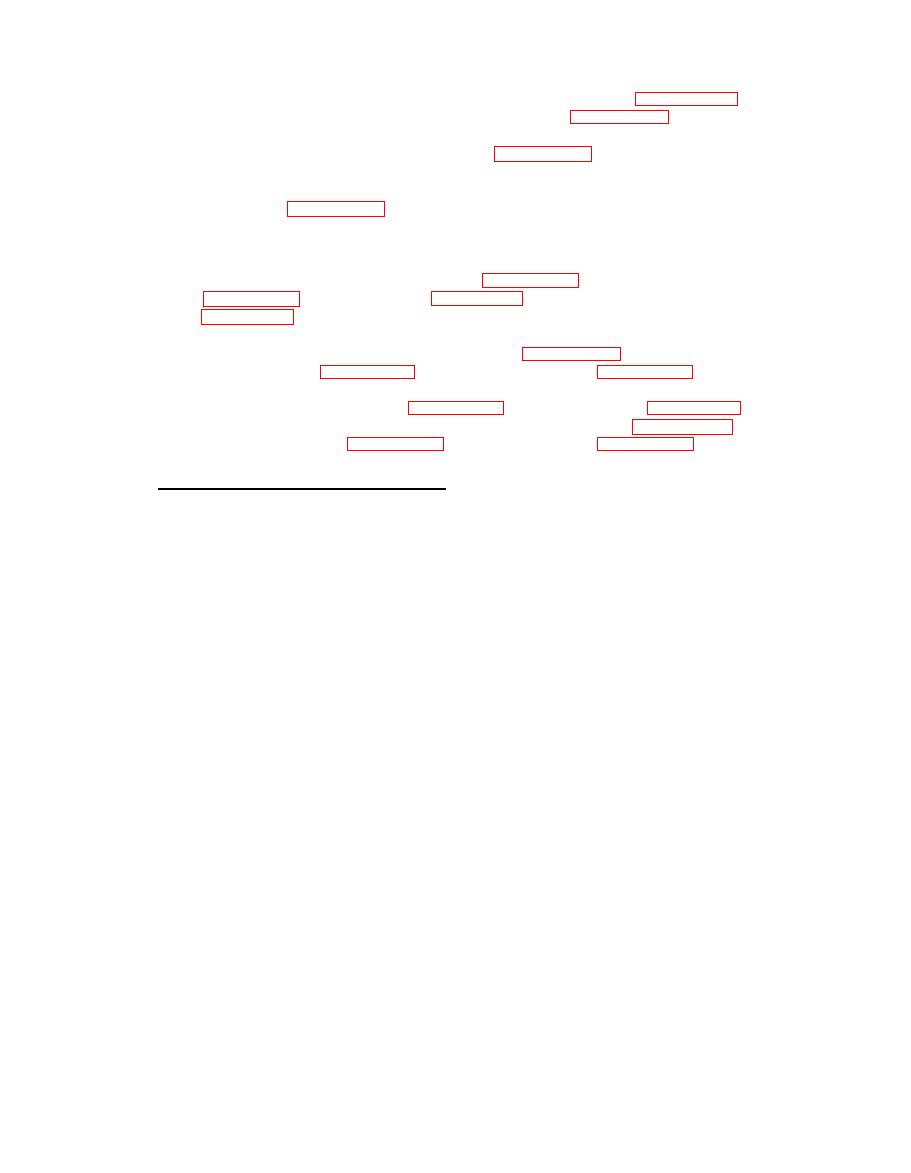

of grease to the throttle and shut off seals (22, figure 8-7).

Assemble the shutoff shaft assembly (10, figure 8-7) from the

opposite side of the housing with a slight rotary motion. Lo-

cate and secure shutoff cam (1, figure 8-7).

(44) Rotate the shaft until a click is heard. This is the governor

arm (7, figure 8-9) engaging the governor thrust sleeve.

(45 ) Check all governor parts for freedom of movement.

(46) Assemble frame assembly (17, figure 8-6), spring sleeve (20,

(47) Install new insulating washers (15, figure 8-6), contact

washers (14, figure 8-6) and locknuts (12, figure 86).

(48) Install new gasket (11, figure 8-6) to cover (10, figure 8-6)

and secure cover to pump with flat washers (8, figure 8-6),

lockwashers (7, figure 8-9) and screws (6, figure 8-9).

Fuel Injection Pump Bench Test.

f.

(1) General. The bench test procedure is based on the following

conditions:

Injection lines are 3/32-inch ID by 30-inches long.

(a)

Fuel readings are based on fuel with a viscosity of 34-36

(b)

SSU at 100oF.

Fuel temperature at 110 to 115oF.

(c)

Nozzles adjusted to opening pressure of 2500 psi (170

(d)

ATS).

(2) Test procedure.

Mount pump securely in diesel injector test stand using a

(a)

suitable adapter. The drive adapter, usually with a ball

bearing, supports the shaft. This pump must be tested

with an intermediate support bearing. Install high pres-

sure injection lines using new gaskets. Leave fuel line

connector screws at pump and injection line nuts at the

nozzles loose. Install fuel inlet and return lines. Install

transfer pump pressure gauge with a shutoff valve as close

to the transfer pump as possible.

NOTE

Transfer pump pressure gauge must be

isolated by shutoff valve at the fuel

injection pump when checking fuel de-

livery and advance movement.

8-33