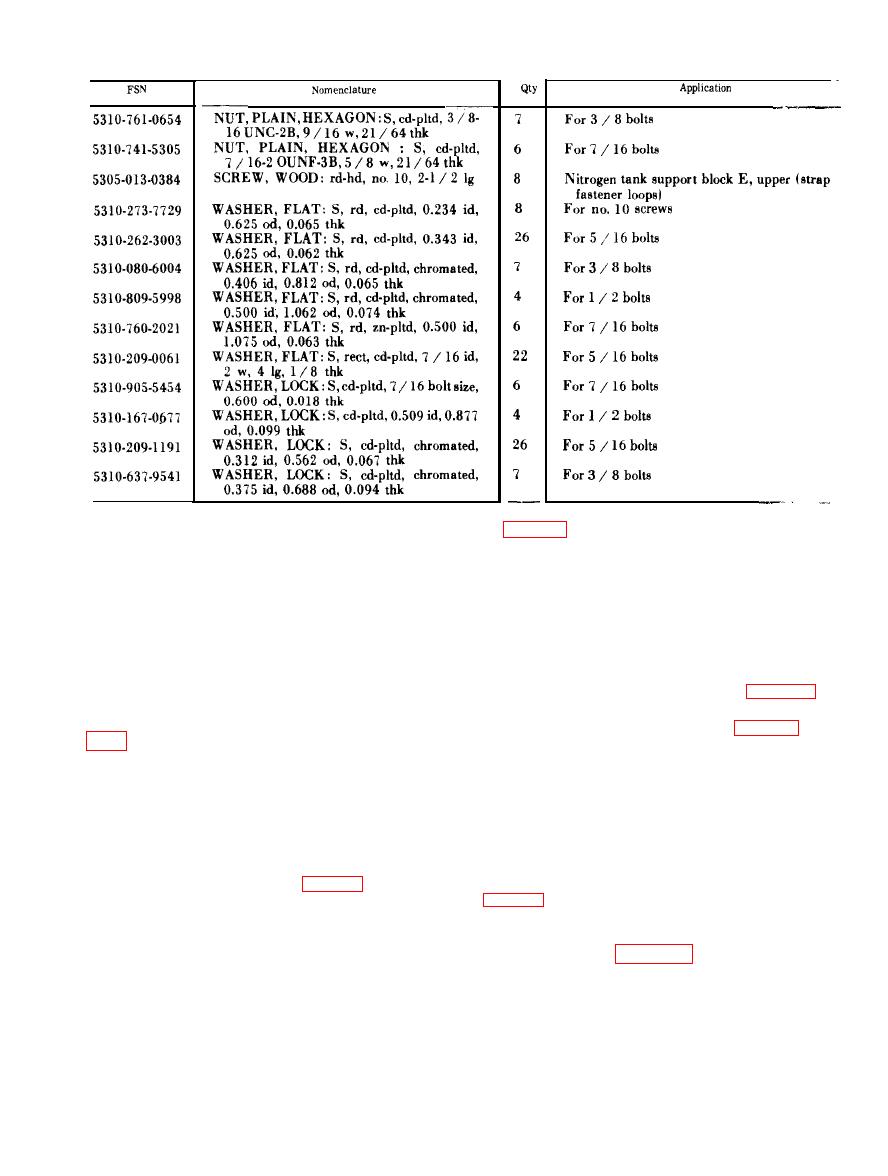

Table 3. Hardware - Continued

d. Unused space in the shop van may be utilized

in figure 1. Mark and drill six 11 / 32-inch holes

for transporting and storing other tools, etc.

through floor of the van. Secure work table with six

e. Ground all electrically powered machinery and

5 / 16-18 x 2-inch hexagon-head machine bolts

power tools to the chassis of the shop van as a safety

5306-225-8504, six 7 / 16-inch inside diameter

precaution against electrical shock to the operator.

rectangular

flat washers 5310-209-0061, six

f. One ground rod with cable assembly is in-

11 / 32-inch inside diameter flat washers 5310-

cluded in the shop set for each shop van. Drive the

262-3003, six 5 / 16-inch split lock washers 5310-

ground rod into the ground and secure the cable

209-1191, and six 5 / 16-18 hexagon plain nuts

assembly to the chassis of the shop van each time

5310-880-7744.

the shop set is placed in operation.

2). Place the storage cabinet (C) flush with work

3. Shop Van. a. Automotive Maintenance Work

table (A) on curbside as shown in figure 1. Mark

Table (A) 4910-543-7771 and (H) 4910-543-7772

and drill four 11 / 32-inch holes through floor of

the van. Secure cabinet with four 5 / 16-18 x 2-inch

(1) There are three work tables to be installed

hexagon-head machine bolts 5306-225-8504, four

in the shop van truck. Two work tables, 4910-543-

7 / 16-inch inside diameter rectangular flat

7771, are designated as A, and one work table,

washers 5310-209-0061, four 11 / 32-inch inside

4910-543-7772, is designated as H.

diameter flat washers 5310-262-3003, four 5 / 16-

(2) Place one automotive maintenance work

inch split lock washers 5310-209-1191, and four

table (A) against the right wall, and other against

5 / 16-18 hexagon plain nuts 5310-880-7744.

the left wall of van. They are located flush with the

c. Hand Operated Arbor Press 3444-243-2654

front of the van as shown in figure 1. Mark and

drill twelve 11 / 32-inch holes through the floor of

the van. Secure work tables with twelve 5 / 16-18 x

press (B) on work table (A), 7-inches from the right

end and 2-inches from the front edge of the table

2 - i n c h hexagon-head machine bolts 5306-225-

top, as shown in figure 1. Mark and drill two

8 5 0 4 , twelve 7 / 16-inch inside diameter rec-

tangular f l a t w a s h e r s 5 3 1 0 - 2 0 9 - 0 0 6 1 , t w e l v e

11 / 32-inch holes through the table top. Secure the

press with two 5 / 16-18 x 3-1 / 2-inch square-neck

11 / 32-inch inside diameter flat washers 5310-

carriage bolts, w / sq nuts 5306-059-1241, two

262-3003, twelve 5 / 16-inch split lock washers

11 / 32-inch inside diameter flat washers 5310-

5 3 1 0 - 2 0 9 - 1 1 9 1 , and twelve 5 / 16-18 hexagon

262-3003, and two 5 / 16-inch split lock washers

plain nuts 5310-880-7744.

(3) Place automotive maintenance work table

5310-209-1191.

(H) flush with work table (A) on roadside as shown

3