TM 1-4920-436-13&P

0013 00

- CONTINUED

1.

Remove cargo strap (Figure 1, Item 3) from eyewash station (Figure 1, Item 1) secured to Cabinet (G) (Figure

1, Item 2) and set eyewash station (Figure 1, Item 1) aside.

2.

Store cargo straps (Figure 1, Item 3) in secure storage location.

3.

Remove two bolts (Figure 1, Item 8), two lock washers (Figure 1, Item 7), and two lat washers (Figure 1, Item

6) from shelter BII box.

4.

Remove eyewash station wall bracket (Figure 1, Item 5) from inside eyewash station.

5.

On expanded wall, align insert holes (Figure 1, Item 4) with eyewash station wall bracket (Figure 1, Item 5).

6.

Inspect two bolts (Figure 1, Item 8) for thread damage or rounded heads.

7.

Replace bolts (Figure 1, Item 8) if damage is detected.

8.

Attach eyewash station wall bracket (Figure 1, Item 1) by installing two bolts (Figure 1, Item 8), two lock

washers (Figure 1, Item 7), and two lat washers (Figure 1, Item 6).

Torque bolts (Figure 1, Item 8) 160-190 in. lbs.

9.

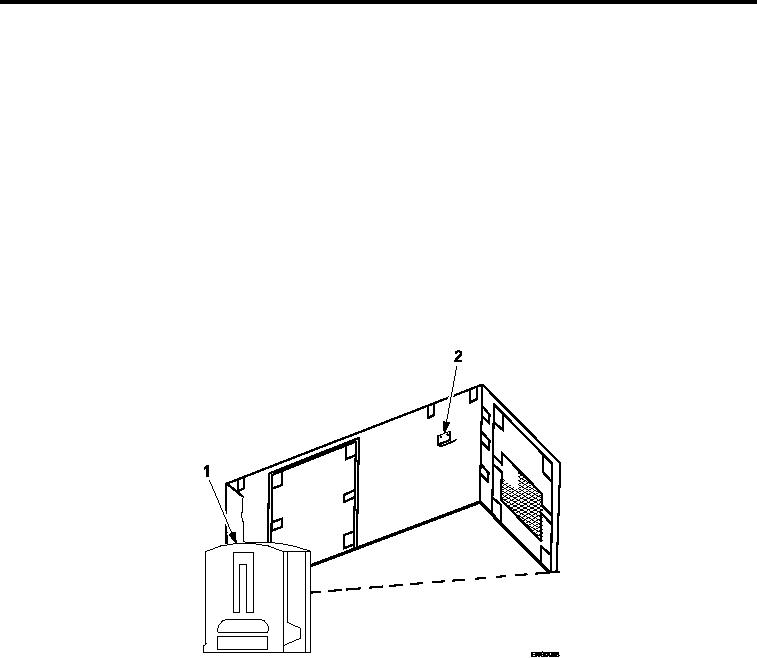

Figure 2.

Position Eyewash Station.

10. Mount eyewash station (Figure 2, Item 1) onto wall bracket (Figure 2, Item 2).

11. Fill eyewash station with eye and face wash fountain solution IAW Sperian Fendall Pure Flow 1000 Eyewash

Station Owner s Manual.

END OF WORK PACKAGE

0013 00-3/4 blank