TM 5-3610-256-14

b. Replace damaged terminals as follows:

(1) Remove damaged terminal by cutting wire as close as possible. If cutting leaves wires too

short, splice as in step a, above.

(2) Install shrink down sleeve of a diameter and length to cover the terminal and wire.

(3) Strip 0.15 inch (3.8 mm) of insulation from end of wire. Crimp new terminal in place.

(4) Position shrink tubing over joint, and heat sleeve to 250 degrees F (121 degrees C) so that the

tubing shrinks to form a tight seal.

c. Replace damaged electrical connectors as follows:

NOTE

Before removing any damaged connector, prepare a diagram

showing the location of each wire in relation to the connector

matching the wire number to the pin letter on the connector.

by

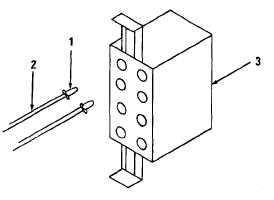

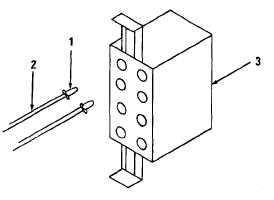

(1) Remove pins (1) and wires (2) from connector (3), and cut wires as close to pins as possible.

(2) Strip 0.25 inch (6.3 mm) of insulation from the end of each wire.

(3) Crimp pins to wire ends.

(4) Install new pins in proper location in connector and reconnect harness,

5-7. MAINTENANCE OF THE AMMONIA PUMP/MOTOR ASSEMBLY.

TOOLS: Hose Clamp Pliers

Safety Goggles

Flat-Tipped Screwdriver

Socket Head Wrench Set

SUPPLIES: Ammonia Pump and Motor

Diaphragm

Connecting Rod

Body

Lubricant

Hose Clamps

5-4