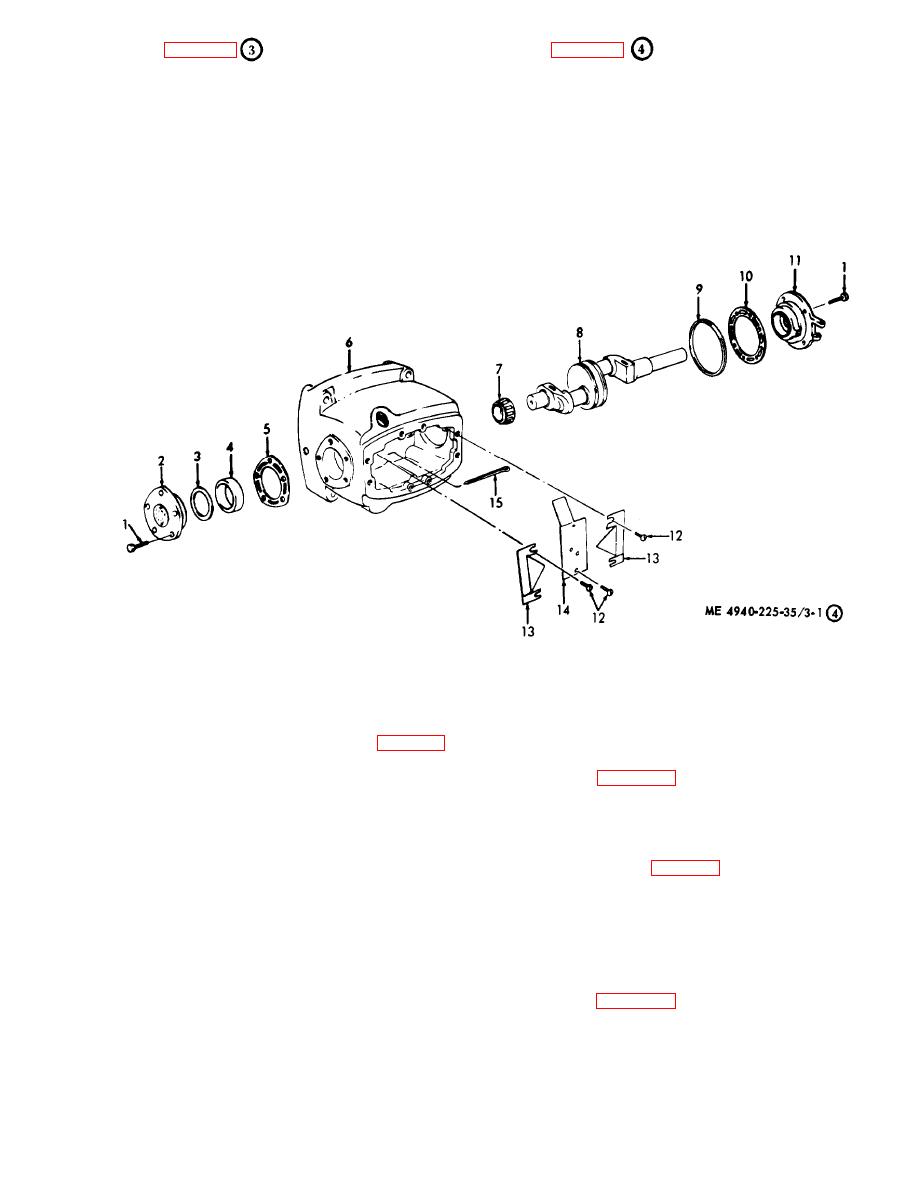

8 Crankshaft

KEY to Figure 3-1

KEY to Figure 3-1

9 Ring

1 Screw

11 Rod assembly

1 Cylinder

10 Gasket

2 End plate

12 Bearing, sleeve

2 Gasket

11 End plate

13 Pin, piston

3 Shim

3 Ring

12 Screw

4 Cup. bearing

14 Piston, high pressure

4 Ring

13 Baffle. side

.5 Gasket

5 Piston. low pressure

15 Ring

14 Baffle. center

6 Pin. cotter

16 Ring

13 Pin, cotter

7 Bearing

17 Screw

7 Screw

8 Lockwasher

18 Pin. piston

19 Pin. cotter

9 Bearing, half

20 Bearing, sleeve

10 Rod assembly

Figure 3-1. Air compressor, disassembly and reassembly (sheet 4 of 4).

( 8 ) Replace all unserviceable parts as

d. Cleaning, Inspection and Repair.

necessary. Weld minor breaks and cracks.

(1) Clean all parts with approved cleaning

e. Reassembly.

solvent and dry thoroughly. Refer to table 1-1 for

tolerances.

(1) Reassemble the air compressor as

illustrated in figure 3-1.

(2) Inspect the intercooler for cracks, breaks,

and dam aged fins.

(2) Use a piston ring compressor to install the

pistons in the cylinder head.

(3) Inspect the cylinders and crankshaft

bearings for cracks, breaks, scoring, wear, warpage,

(3) The crankshaft bearing adjustment is

made by removing or adding shims at the small

and other damage or defects.

crankcase end plate (table 1-1 ).

(4) Inspect the cylinder head for cracks,

breaks, warpage, and other damage.

f. Installation. Install the air compressor (TM

5-4940-225-12).

(5) Inspect the valve plate and valves for wear

and defects.

3-2. Air Compressor Drive Motor

(6) Inspect the crankcase for cracks, breaks,

a. Removal. Remove the drive motor (TM 5-

and damaged threads.

4940-225-12).

(7) Inspect the pistons, rings, and pins for

b. Disassembly. Disassemble the drive motor as

dam age and defects.

illustrated in figure 3-2.

3-5