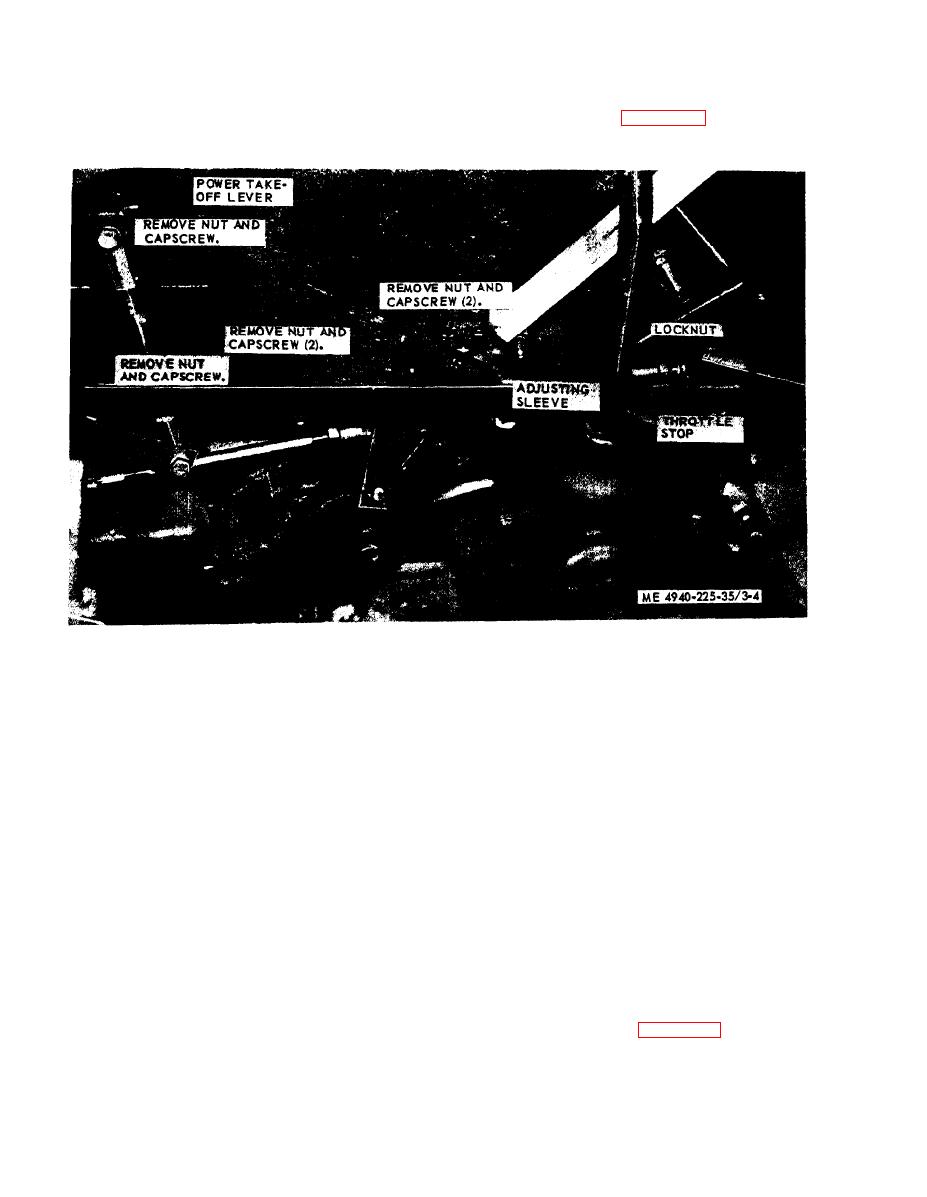

3-6. Overspeed Linkage (Model SEORL Only)

The overspeed linkage which prevents engine

overspeed after the power take-off lever is engaged,

a. G e n e r a l . T h e t r u c k e n g i n e p r o v i d e s

is accessible by removing the truck cab center

mechanical power for driving the dynamotor-

floorboard.

welder, and the operating speed is 1000 or 1200

rpm to furnish 50 or 60 cycle alternating current.

overspeed linkage.

Figure 3-4. Overspeed linkage. removal and installation. (Model SEORL Only/

3-7. Overspeed Safety Switch (Model SEORLT

c. Adjustment.

Only)

(1) Start engine and engage power take-off

(TM 5-4940-225-121.

a. On-Equipment Testing.

(2) With transmission in fifth gear position.

(1) Tag and disconnect all electrical leads at

slowly depress accelerator until accelerator linkage

the resistor and the solenoid coil lead at the ter-

makes contact with throttle stop.

minal strip.

(3) At full throttle tachometer reading should

12) Use a multimeter and test the resistor for

he 1200 rpm for 60 cycle and 1000 rpm for 50

smooth increments in resistance from 0 to 1,000

cycle electricity y.

ohms. Replace a defective resistor.

(4) To adjust engine speed, loosen locknut

(3) Use a multimeter to measure the

and turn throttle stop in or out of adjusting sleeve.

resistance of the 300 ohm coil. If the variance is

Turn throttle stop clockwise to increase speed and

greater than plus or minus 2 percent, replace the

counterclockwise to decrease speed.

coil.

(5) After proper engine speed is obtained,

(4) Connect a multimeter to circuits 115 and

tighten locknut against adjusting sleeve.

116: continuity should not be indicated. Activate

the overspeed switch by hand: if continuity is not

Note. If further adjustment is required. loosen the

indicated, replace the microswitch.

locknuts on both ends of the adjusting sleeve and change

(5) Connect previously tagged leads as

position of the sleeve as required.

necessary.

d. Installation. Install in reverse order of

the overspeed safety switch assembly.

b above.

3-8