TM 55-4920-215-15

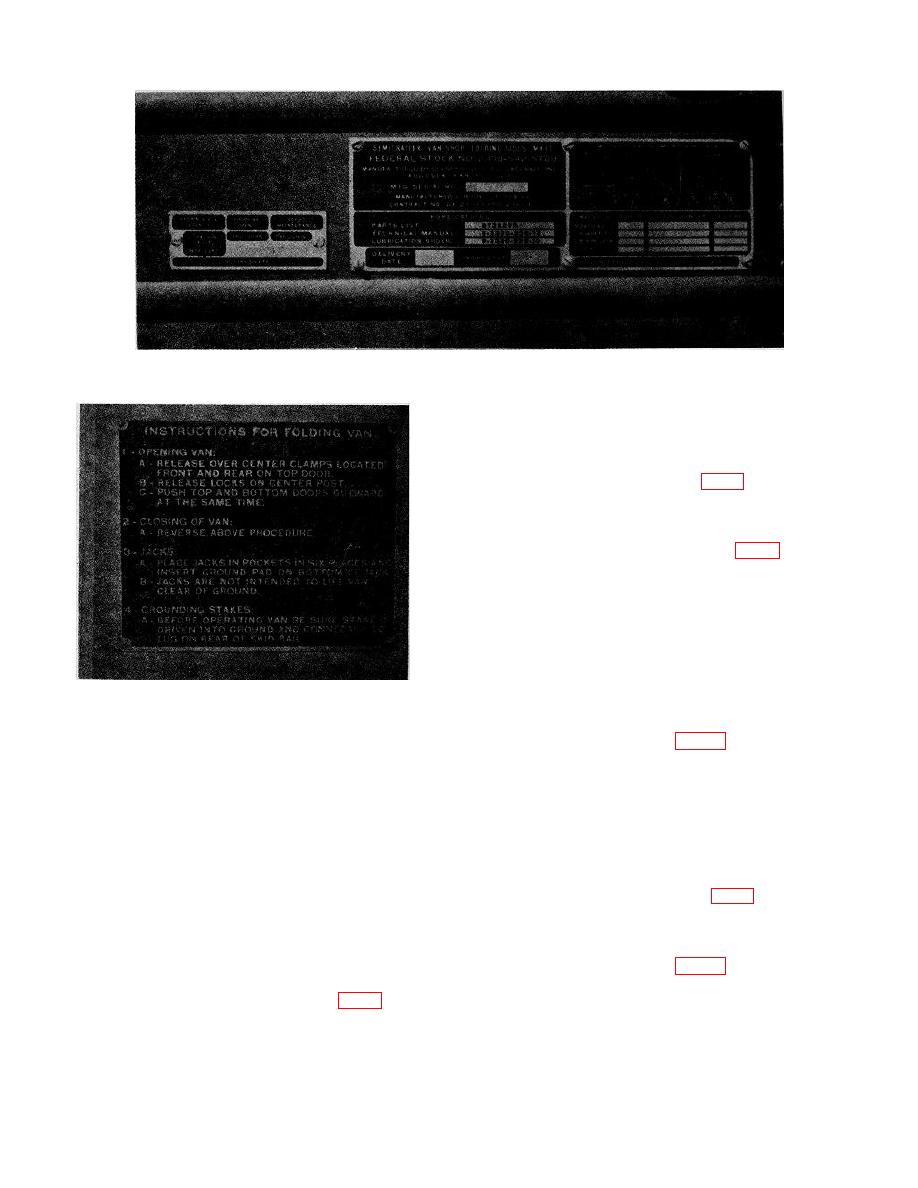

Figure 2. Identification pates, shop set, C-6.

Safety devices ............ Safety disconnect switch.

Controls ...................... Thermal-magnetic circuit

breaker panel; 14 break-

era (fig. 4).

Electrical

connections,

equipment ................... Receptacles and circuit

breakers (fig. 4).

(2) Pneumatic system

Power source .............. External; compressor or

storage tank.

Pneumatic power

requirements ............. 5 cfm at 175 psi working

pressure

Pneumatic

Figure 3. Instruction plate, shop set, C-6.

connections,

shop.......................... Quick disconnect fittings

Generator mount- Skid type.

Pneumatic

ing.

connections,

Generator rating ........... Single and three-phase, 10

equipment ................ Quick disconnect fittings;

kw, 208 v, ac, line-to-

air hose and adapters

line, 120 v, line-to-neutral

Safety devices ............. Safety relief valve.

or line-to-line, three-

Controls ....................... Shutoff valve; oil and water

phase, 60 cycle operation;

separator, gages, regula-

or 10 kw, 120-240 v, line-

tors, valves, and check

to-line, single phase, 60

units (fig. 5).

cycle operation.

Pneumatic

Electrical

connections,

connections,

equipment ................ -Quick disconnect fittings

shop ......................... Power cable, male to female

joy plug for shop or pot

(3) Utility System

head assembly for auxil-

Type equipment .......... Bench tops maple, size A;

iary operation (fig. 8).

storage cabinet, Type I

and III.

6