TM 55-4920-215-15

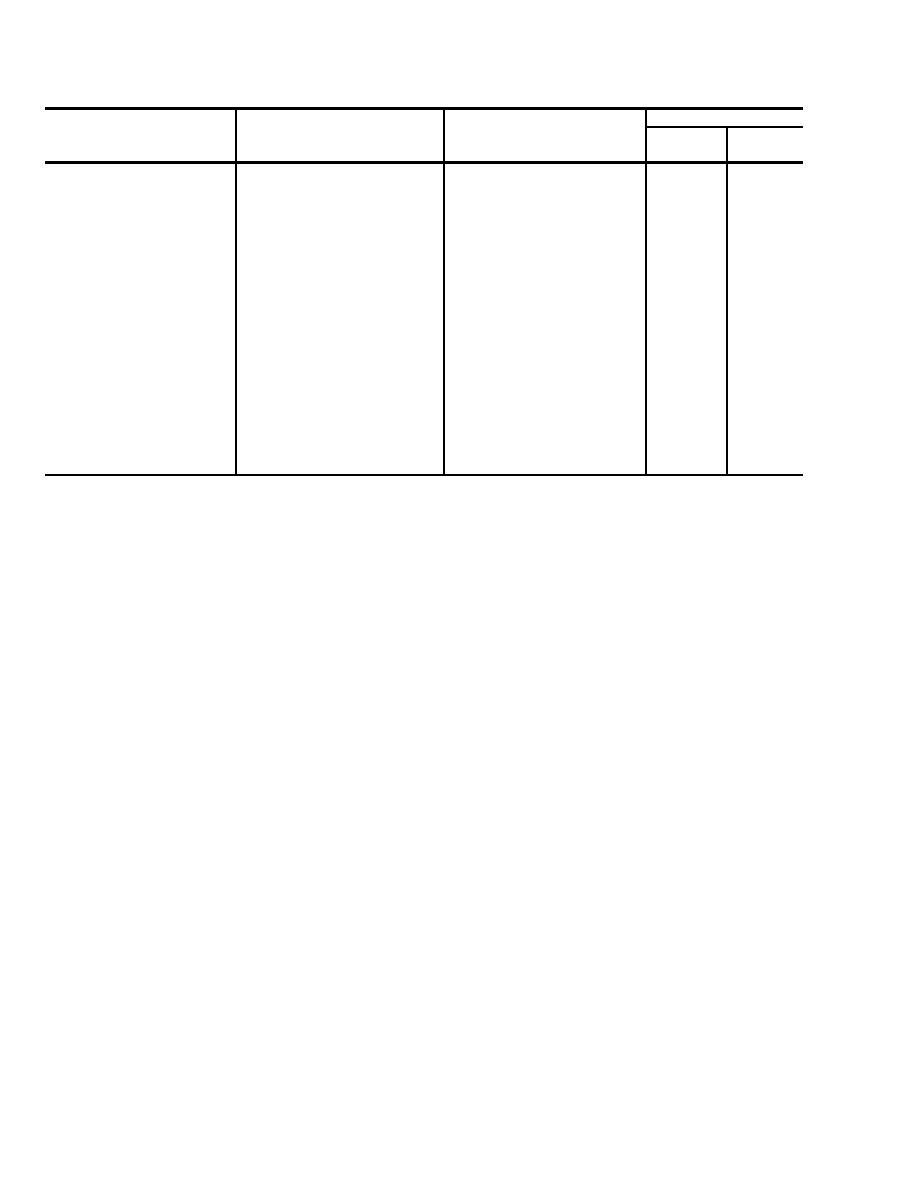

Table II. Preventive Maintenance Services-Continued.

3. Hydraulic System

Intervals

Item

Inspect

Service

Inspected

for

required

Weekly

Monthly

STORAGE CABINET

Sticking, binding and dis-

Lubricate (ch. 6, sec. II),

X

DRAWERS.

tortion.

aline or straighten as

necessary.

STORAGE CABINET

Alignment, ease of opera-

Aline hinges, lubricate

X

HINGE POINTS.

tion, and condition.

(ch. 6, se. II) or replace

as necessary.

STORAGE CABINET

Corrosion, rust, chipped, or

Remove corrosion and rust

X

EXTERIORS.

peeling paint.

(ch. 3, sec II), touchup or

repaint as necessary.

STORAGE CABINET

Security, ease of operation

Tighten bolts, re-aline, re

X

LOCKING DEVICES.

and alignment

position, or replace as

necessary.

STORAGE CABINET

Security.

Tighten or replace mount-

X

MOUNTINGS

ing bolts a necessary.

BENCH TOP SURFACE.

Nicks, gouges., scratches.

Sand out, refinish (ch. 6).

X

BENCH TOP

Security.

Tighten or replace screws

X

MOUNTINGS.

or bolts as necessary.

Section IV. TROUBLESHOOTING

38. Electrical Equipment Stops During Operation

35. Us of Troubleshooting Section

Probable cause

Possible remedy

This section provides information useful in

diagnosing and correcting unsatisfactory operation or

Power cord of equipment

failure of the shop set or any of its components. Each

not properly plugged In-

trouble symptom stated is followed by a list of probable

to receptacle

Remove plug from recep-

cause of the trouble.

The possible remedy

tacle and reinsert fully

recommended is described opposite the probable cause.

into receptacle.

Equipment overheated ........Reduce operating speed; al-

36. Procedure

low equipment to cool and

To correct malfunctioning of equipment, the

re-start.

cause should be systematically isolated in accordance

Circuit breaker tripped to

with instructions in the following paragraphs. If the

"OFF" position..................circuit breaker to

correction of the malfunction is beyond the scope of the

" N" position; re-start

O

operator's function, refer the discrepancy to the proper

equipment.

maintenance echelon for correction.

Cause beyond maintenance

scope of operator .............Notify second maintenance

37.

Electrical Equipment Operates at Slow or

echelon.

Reduced Speed

Probable cause

Possible remedy

39. Electrical Equipment Will Not Start

Loose connectors ................Tighten connectors.

Probable cause

Possible remedy

One circuit breaker in

Power cord of equipment

"OFF" potion (0

not plugged into recep-

volt equipment) ................Return breaker to "ON"

tacle.................................Inert plug of equipment

position.

cord into receptacle.

Cause beyond maintenance

No power from genea-

scope of operator .............Notify road maintenance

tor ....................................Check for generator op

ation; restart generator.

Circuit breaker in electri-

cal panel in OFF

Re-set circuit breakers to

position ............................ ON position.

19