TM 9-243

SAFETY

1.

Keep work, scraper, and hands free from grease

and oil when using a scraper.

2.

Keep scrapers sharp at all times, (except the carbon

scrapers), since a dull scraper is more apt to slip

and cause injury.

3.

Use the scrapers only for their intended purposes.

NOTE

Carbon scraper blades are fairly dull

to prevent scoring of a piston and/or

cylinder wall.

USING A BEARING SCRAPER

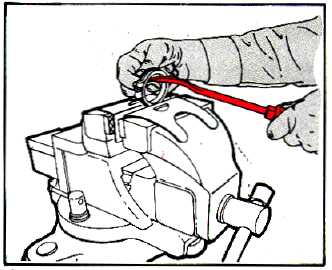

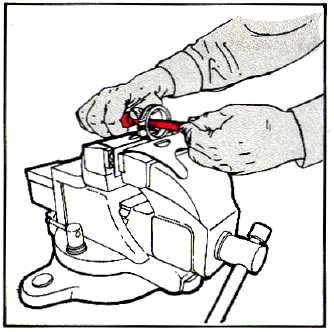

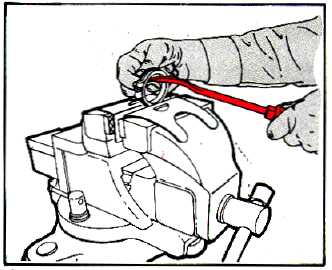

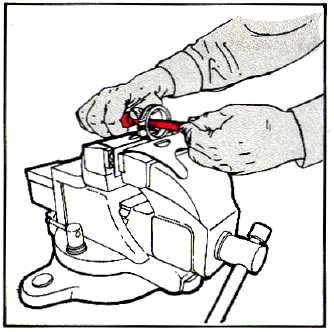

1

Place the bearing to be scraped on a bench or other

suitable working surface.

2

Use both hands on the bearing scraper. One hand

should be at the end of the handle while the other

hand steadies the tool.

3

Use the hand at the end of the handle to twist the

tool. Use very light pressure and remove a small

amount of metal with the twisting stroke. If too

much pressure is applied, the scraper will chatter

and leave a rough, uneven surface.

4

Start at one top side of bearing cap. Work down,

and then up to the top of the other side. Do not

scrape lengthwise.

5

Repeat procedure until the required amount of

material has been removed to fit the bearing onto

the shaft.

CARE OF SCRAPERS

1.

Keep scrapers sharp (except carbon scrapers) by

sharpening or grinding.

NOTE

Carbon scraper blades are fairly dull

to prevent scoring of a piston and/or

cylinder wall.

2.

When a scraper is not in use, coat the blade with a

film of light oil.

3.

Hang or store scrapers separately to protect the

cutting edge. Do not throw scrapers in with other

tools. This will damage the cutting edges.

4.

For long-term storage, coat all metal parts with rust-

preventive compound and store in a dry place.

30-3/(30-4 blank)