TM 9-243

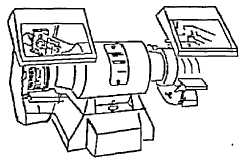

USING ELECTRIC BENCH GRINDERS

The electric powered bench mounted grinder is used to

sharpen tools, dress screwdrivers, and to shape and

smooth metal stock. Avoid grinding of non-ferrous

metals (brass, copper, aluminum, etc.) on the grinder

supplied: special grinding wheels are required for this

purpose.

BENCH GRINDER

The bench grinder available at the sites is equipped with

two different types of grinding wheels. One wheel is

coarse and is used for rough grinding. The other is fine

and is used for tool sharpening and finish grinding.

These grinders are also equipped with safety shields

and tool rests. The tool rest should be adjusted so that

the space between the grinding wheel and the tool rest

is approximately 1116 inch, but never over 1/8 inch.

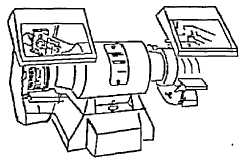

MOUNTING GRINDING WHEELS ON SPINDLES

Use the following

procedure when grinding

wheels are to be

mounted on the spindle.

1.

Inspect the wheel for

flaws and make the

"ring test."

2.

Clean

the

bearing

surfaces

of

the

wheel, flanges and

spindle so that the clamping pressure will be evenly

distributed.

3.

Check the speed of the spindle to make sure that it

is not running too fast for the type and size of wheel.

4.

Make sure the hole in the wheel bushing is the right

size for the spindle. (neither too small nor too large.)

5.

Use flanges that are recessed and large enough

to clamp the wheel well toward its circumferences.

6.

Tighten the spindle end nuts just enough to keep the

wheel from moving out of position between the

flanges.

WARNING

7.

Before turning on power, make sure that the wheel

runs true and will strike no obstructions

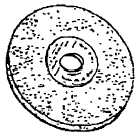

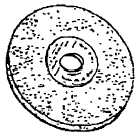

GRINDING WHEEL "RING" TEST

New grinding wheels should be promptly unpacked upon

receipt and given the "ring" test for damage suffered.

Also, give this test immediately before mounting either a

new or used wheel on the spindle, especially if the wheel

has been in storage for a long time.

The" ring " test readily discloses defects in grinding

wheels, including flaws and cracks, even though most

defects are invisible to the naked eye.

Make the test by suspending the wheel free and clear

and tapping it gently with a light wooden implement. A

wooden screwdriver handle would be appropriate for a

light wheel. A wooden mallet would be good for a heavy

wheel.

Sound and undamaged wheels will emit a clear metallic

tone when tapped. If the wheel is defective there will be

no ring.

Wheels bonded with organic material do not emit the

same clear metallic sound as do verified and silicate

wheels.

Any wheel should be dry and free of sawdust when the

"ring" test is given; otherwise the sound will be

deadened.

GRINDING SUGGESTIONS

Listed below are several suggestions that, if followed,

will eliminate machine abuse and provide maximum

protection for the operator:

Wear safety glasses at all times when working

near

the

grinder,

including

the

period

of

adjusting guards and tool rest. Do not remove

the glasses until the job is completed and the

machine shut off.

52-14 Change 3