TM 9-243

TYPES AND USES

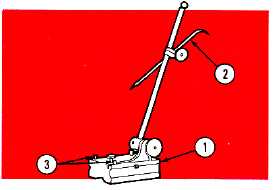

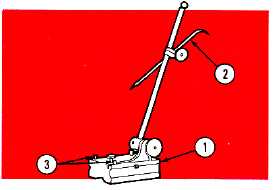

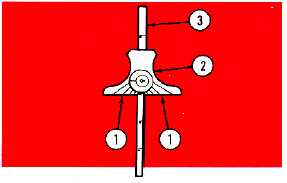

SURFACE GAGE

A surface gage is a measuring tool used to transfer

measurements to work by scribing a line, and to indicate

the accuracy or parallelism of surfaces. The surface

gage consists of a base with an adjustable spindle (1) to

which may be clamped a scriber or an indicator (2).

Surface gages are made in several sizes and are

classified by the length of the spindle. The smallest

spindle is 4 inches long, the average 9 to 12 inches, and

the largest 18 inches. The scriber is fastened to the

spindle with a clamp. The bottom and the front end of

the base of the surface gage have deep V-grooves. The

grooves allow the gage to measure from a cylindrical

surface. The base has two gage pins (3). They are

used against the edge of a surface plate or slot to

prevent movement or slippage.

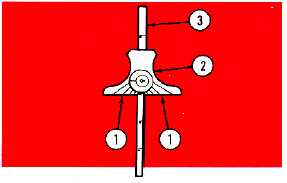

RULE DEPTH GAGE

A rule depth gage measures the depth of holes, slots,

counterbores, and recesses. Some rule depth gages,

such as the one shown above, can also be used to

measure angles. This is done by using the angle marks

(1) located on the sliding head (2). The rule depth gage

is a graduated rule (3) with a sliding head (2) designed

to bridge a hole or slot. The gage holds the rule at a

right angle to the surface when taking measurements.

This type has a measuring range of 0 to 5 inches. The

sliding head has a clamping screw so that it may be

clamped in any position. The sliding head is flat and

perpendicular to the axis of the rule. It ranges in size

from 2 to 2-5/8 inches wide and from 1/8 to 1/4 inch

thick.

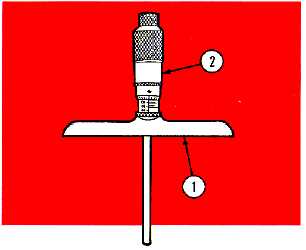

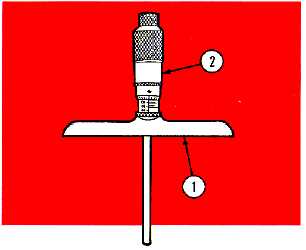

MICROMETER DEPTH GAGE

The micrometer depth gage consists of a flat base (1)

that is attached to the barrel of a micrometer head (2).

These gages have a range from 0 to 9 inches,

depending on the length of extension rod used. The

hollow micrometer screw has a 1/2 or 1 inch range.

Some are provided with a ratchet stop. The flat base

ranges in size from 2 to 6 inches. Several extension

rods are supplied with this type gage.

NOTE

For

additional

information

on

micrometers, see chapter 7 in this

manual.

14-2