TM 9-243

TYPES AND USES

Ring and snap gages and precision gage blocks are

used as standards to determine whether or not one or

more dimensions of a manufactured post are within

specified limits. Their measurements are included in

the construction of each gage, and they are called fixed

gages. However, some snap gages are adjustable.

Gages are used for a wide range of work, from rough

machining to the finest tool and die making. The

accuracy required of the same type of gage will be

different, depending on the use.

RING GAGES

SNAP GAGE NONADJUSTABLE

The following classes of gages and their limits of

accuracy are standard for all makes: Class X Precision

lapped to close tolerances for many types of masters

and the highest quality working and inspection gages.

Class Y Good lapped finish to slightly increased

tolerances for inspection and working gages.

Class Z Commercial finish (ground and polished, but not

fully lapped) for a large percentage of working gages in

which tolerances are fairly wide, and where production

quantities are not so large.

Class ZZ (Ring gages only). Ground only to meet the

demand for an inexpensive gage, where quantities are

small and tolerances liberal.

SNAP GAGE - ADJUSTABLE

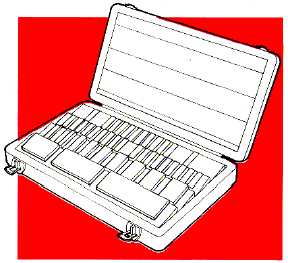

GAGE BLOCKS

The table below lists the tolerances for ring gages in

each class:

RING

TO AND

GAGES

ABOVE INCL

X

Y

Z

ZZ

0.029

0.825

0.00004

0.00007

0.00010

0.00020

0.825

1.510

0.00006

0.00009

0.00012

0.00024

1.510

2.510

0.00008

0.00012

0.00016

0.00032

2.510

4.510

0.00010

0.00015

0.00020

0.00040

4.510

6.510

0.00013

0.00019

0.00025

0.00050

6.510

9.010

0.00016

0.00024

0.00032

0.00064

9.010

12.010

0.00020

0.00030

0.00040

0.00080

X

Precision lapped

Y

Lapped

Z

Ground or polished (grinding marks may be in evidence)

ZZ

Ground only

15-2