TM 9-243

TYPES AND USES - Continued

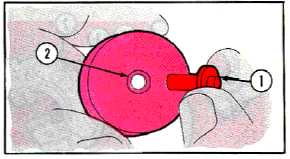

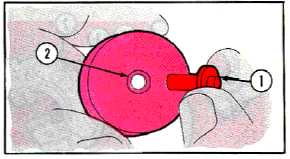

USING A RING GAGE

To check the shank diameter of a pivot stud.

1. Line the stud (1) up with the hole (2) and press in

gently. If the stud will not go in, the shank is too large.

If it will go in, the stud is not oversize.

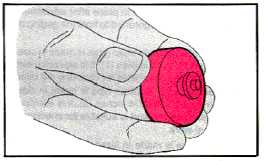

2. With the stud in the hole, check the piece for taper

and out-of-roundness by sensing any wobble.

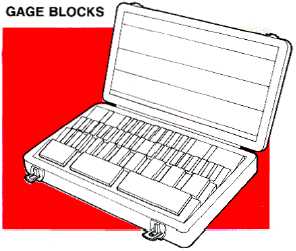

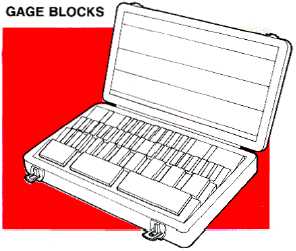

Gage blocks are available in sets of from 5 to as many

as 85 blocks of different dimensions. Precision gage

blocks are made from a special alloy steel. They are

hardened, ground, and then stabilized over a period of

time to reduce subsequent waxing. They are

rectangular in shape with measuring surfaces on

opposite sides. The measuring surfaces are lapped and

polished to an optically flat surface and the distance

between them is the measuring dimension. This

dimension may range from 0.010 inch up to 20 inches.

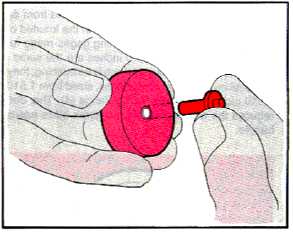

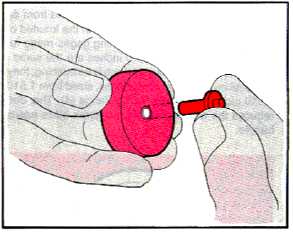

3. After checking the part in the GO gage, check it in

the NO GO gage. The stud must not enter this gage to

establish it as being between the desired limits.

NOTE

The GO ring gage controls the

maximum dimension of a part and

NO GO plug gages control the

minimum

dimension

of

a

hole.

Therefore, GO gages control the

tightness of fit of mating parts and

NO GO gages control the looseness

of fit of mating parts.

15-4