TM 9-243

TYPES AND USES

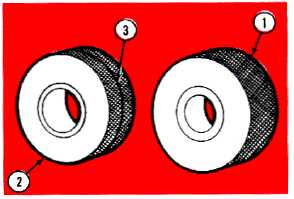

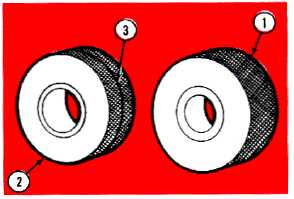

RING GAGES

The plain ring gage is an external gage of circular form.

For sizes between 0.059 and 0.510 inch, ring gages are

made with a hardened bushing pressed into a soft body.

The thickness of the gage will range from 3/16 to 1-5/16

inches. On ring gages, the GO gage (1) is larger than

the NO GO gage (2). The GO and NO GO ring gages

are separate units. They can be distinguished from

each other by an annular groove (3) cut in the knurled

outer surface of the NO GO gage. Ring gages made for

diameters of 0.510 to 1.510 inches are the same as

those shown above, except there is no bushing; they are

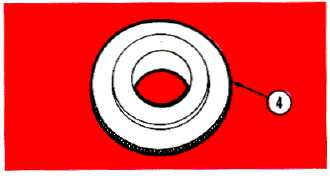

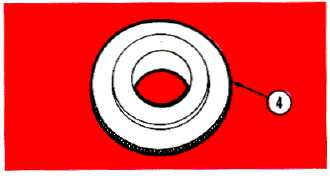

made all in one piece. Ring gages, sized from 1.510 to

5.510 inches are made with a flange (4). This design

reduces the weight, making the larger sizes easier to

handle.

Ring gages are used more often in the inspection of

finished parts than parts in process. The reason for this

is that the finished parts are usually readily accessible;

whereas, parts in a machine that are supported at both

ends would have to be removed to be checked.

SNAP GAGES

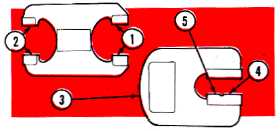

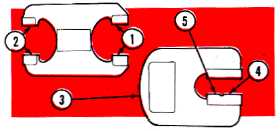

The plain snap gage is made in two general types, the

nonadjustable and adjustable. The nonadjustable type

is a solid construction, having two gaging members, GO

(1) and NO GO (2) as shown above. The part to be

inspected is first tried on the GO side and then the gage

is reversed and the part tried on the NO GO side. Some

solid snap gages (3) have combined gaging members in

the same set of jaws as shown above, known as a

progressive snap gage. The outer member (4) gages

the GO dimension and the inner member (5) the NO GO

dimension.

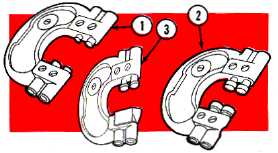

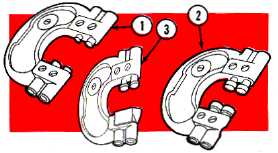

Three standard designs of the adjustable type are

available, consisting of a light, rigid frame with

adjustable gaging pins, buttons, or anvils. These pins or

buttons may be securely locked in place after

adjustment, and locking screws are tightened to hold the

gaging dimensions.

One type of adjustable snap gage is made in sizes that

range from 1/2 to 12 inches (1). It is equipped with four

gaging pins and is suitable for checking the dimension

between surfaces. Another type is made in sizes that

range from 1/2 to 11-1/4 inches (2). It is equipped with

four gaging buttons and is suitable for checking flat or

cylindrical work.

The third type is made in sizes from 1/2 to 11-5/8 inches

(3). It is equipped with two gaging buttons and a single

block anvil, and is especially suitable for checking the

diameters of shafts, pins, studs, and hubs.

15-3