TM 9-243

USING AN ADJUSTABLE SNAP GAGE - Continued

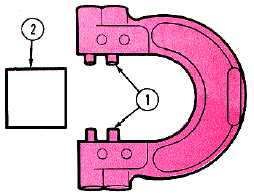

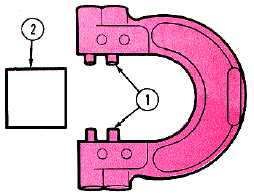

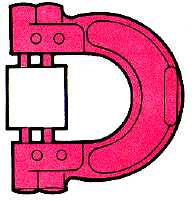

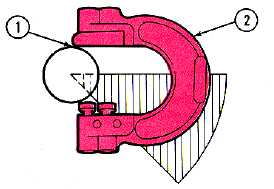

GAGING FLAT PARTS

1.

Position gage so that the pins or buttons (1) are

square with the flat surfaces on the part (2).

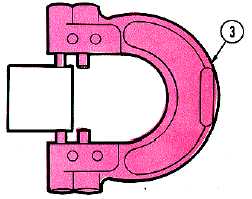

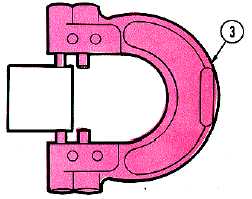

2.

Using a slight hand pressure, push the gage (3)

over the part.

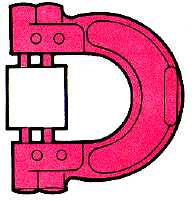

3.

If the part is within limits, the NO GO pins will

stop the part.

4.

If the part is undersize, it will be possible to push

it past the NO GO pins.

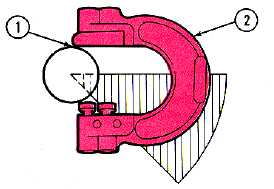

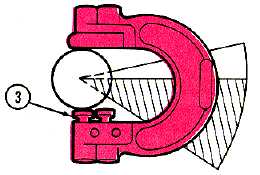

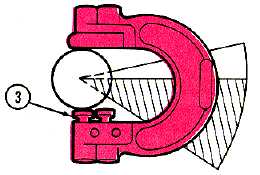

GAGING CYLINDRICAL PARTS

1.

Locate the gage on the part with the solid anvil

1 ) on top. Rock the gage (2) as indicated by

the shaded segment above, where the GO

dimension is checked.

2.

If the shaft is not oversized, the first button (3)

will pass over it easily.

15-6