TM 9-243

USING AN ADJUSTABLE SNAP GAGE - Continued

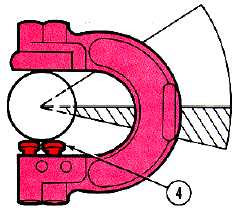

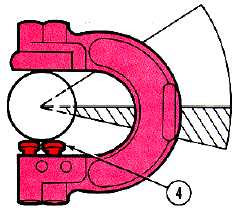

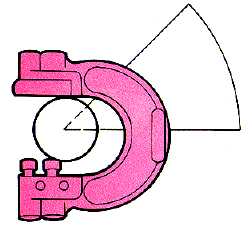

3.

Move the gage to the position shown above. If

the NO GO button (4) stops the gage, the shaft

is within limits.

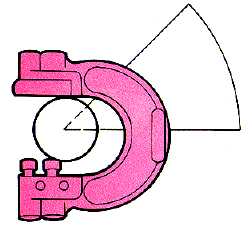

4.

If the gage can be rocked further to the position,

as shown, the part diameter is too small, since

it has passed the NO GO button.

HOW TO USE PRECISION GAGE BLOCKS

Before using gage blocks, remove the coat of rust

preventive compound with a chamois or a piece of

cleansing tissue or by cleaning with an approved

solvent. Gage blocks and any measuring tool used with

them must be free of grease, oil, dirt, and other foreign

matter to avoid a lapping action whenever the block is

moved, and to ensure accurate measurement. When

using gage blocks, take particular care when measuring

hardened work to avoid scratching the measuring

surfaces.

NOTE

When building gage blocks (wringing

them together) to obtain a desired

dimension, care should be exercised

to avoid damaging them.

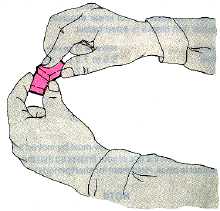

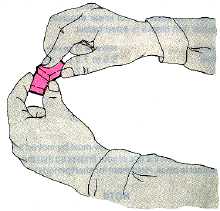

1.

Bring the blocks together flat and move them

slightly back and forth. This minimizes

scratching, as it will detect any foreign particles

between the surfaces.

15-7