TM 9-243

TYPES AND USES - Continued

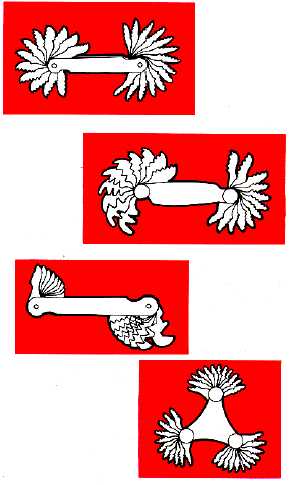

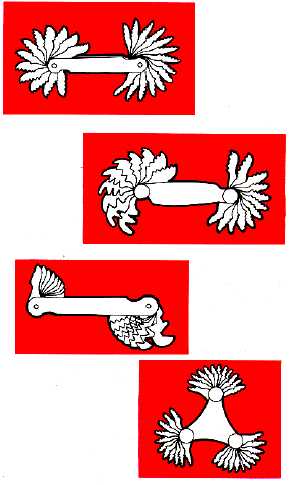

SCREW PITCH GAGES

Screw pitch gages are made for checking the pitch of

U.S. Standard, Metric, National Form, V-form, and

Whitworth cut threads. These gages are grouped in a

case or handle, as are the thickness gages. The

number of threads per inch is stamped on each blade.

Some types are equipped with blade locks. The

triangular shaped gage has 51 blades covering a wide

range of pitches, including 11-1/2 and 27 threads-per-

inch for V-form threads.

Screw pitch gages are used to determine the pitch of an

unknown thread. The pitch of a screw thread is the

distance between the center of one tooth to the center of

the next tooth.

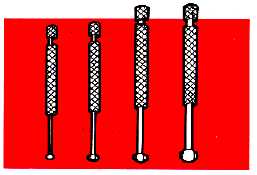

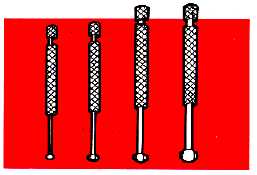

SMALL HOLE GAGE SET

Small hole gages are adjustable, having a rounded

measuring member. A knurled screw in the end of the

handle is turned to expand the ball-shaped end in small

holes and recesses. A micrometer caliper is used to

measure the ball end. Maximum measuring capacity is

1/2 inch. This set of 4 or more gages is used to check

dimensions of small holes, slots, grooves, and so forth

from approximately 1/8 to 1/2 inch in diameter.

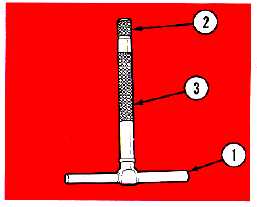

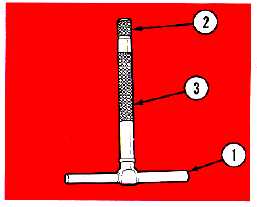

TELESCOPING GAGES

Telescoping gages are used to gage larger holes and to

measure inside distances. These gages are equipped

with a plunger (1) that can be locked in the measuring

position by a knurled screw (2) in the end of the handle

(3). Maximum measuring capacity is 6 inches.

Measurements must be calipered on the gage by a

micrometer, as in the case of the small hole gages.

They are also used when measurements cannot be

taken with a standard micrometer. Telescoping gages

are particularly adaptable for roughly bored work and

odd sizes and shapes of holes. Compress the plungers

and

lock

them

by

turning

handle

screw.

16-3