TM 9-243

TYPES AND USES - Continued

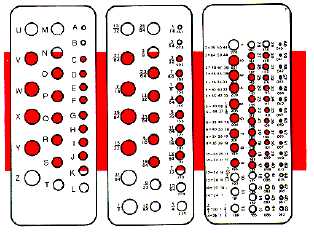

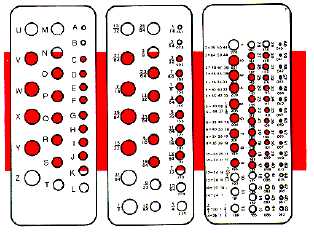

DRILL GAGES

The twist drill and drill rod gage has a series of holes

with size and decimal equivalents stamped adjacent to

each hole. One gage measures drill sizes Nos. 1 to 60;

the other gage measures drill sizes 1/16 to 1/2 inch in

1/64 inch intervals. Drill gages determine the size of a

drill and indicate the correct size of drill to use for given

tap size. Drill number and decimal size are also shown

in this type gage. Letter size drill gages are also

available. Each drill hole is identified by a letter instead

of a number, decimal, or fraction.

MARKING GAGES

Marking gages are made of wood or steel. They consist

of a graduated beam about 8 inches long on which a

head slides. The head can be fastened at any point on

the beam with a thumbscrew. The thumbscrew presses

a brass shoe tightly against the beam and locks it firmly

in position. A steel pin or spur (1) marks the wood and

projects from the beam about 1/16 inch.

A marking gage is used to mark off guidelines parallel to

an edge, end, or surface of a piece of wood. It has a

sharp spur or pin which does the marking. A marking

gage must be adjusted by setting the head the desired

distance from the spur.

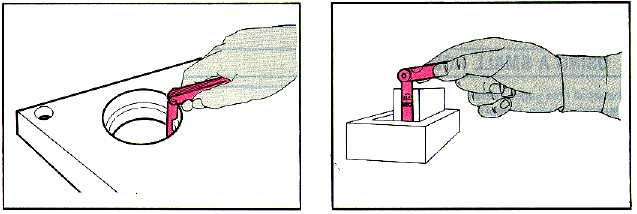

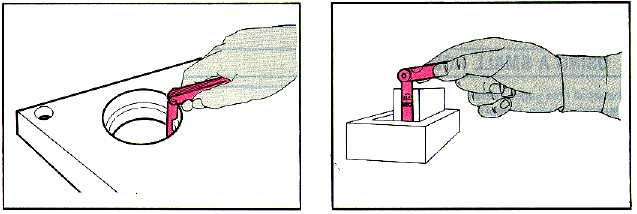

USING A THICKNESS GAGE

Thickness (feeler) gages are used in one of two ways:

as a means for determining a measure or a means for

adjusting to a definite limit. A thickness gage is used to

check piston ring gap clearance in a cylinder bore.

A long blade thickness gage is used to determine the fit

between large mating surfaces. By combining blades it

is possible to obtain a wide variation of thickness.

16-5