TM 9-243

TYPES AND USES - Continued

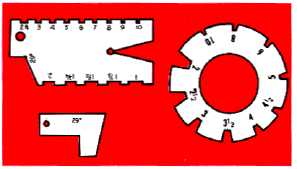

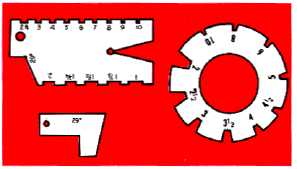

THREAD CUTTING TOOL GAGES

Thread cutting tool gages are hardened steel plates with

cutouts around the perimeter. Each cutout is marked

with a number that represents the number of threads per

inch. These gages provide a standard for thread cutting

tools.

They have an enclosed angle of 29 degrees and include

a 29 degree setting tool. One gage furnishes the correct

form for square threads and the other for Acme standard

threads.

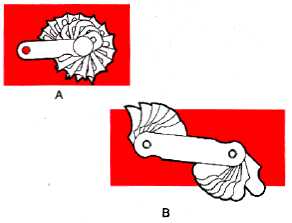

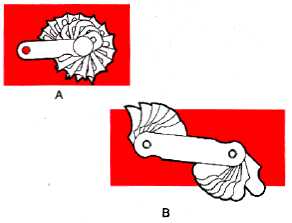

FILLET AND RADIUS GAGES

The blades of fillet and radius gages are made of

hardrolled steel. The double-ended blades of the gage

have a lock which holds the blades in position. The

inside and outside radii are on one blade on gage (A).

The other gage (B) has separate blades for inside and

outside measurements. Each blade of each gage is

marked in 64ths. Each gage has 16 blades.

DRILL POINT GAGE

The drill point gage consists of a 6-inch hook rule with a

59 degree sliding head that slides up and down the rule.

The sliding head can be locked at any position on the

rule and is graduated in 1/32 inch. This gage is used to

check the accuracy of drill cutting edges after grinding.

It is also equipped with a 6-inch hook rule. This tool can

be used as a drill point gage, hook rule, plain rule, and a

slide caliper for taking outside measurements.

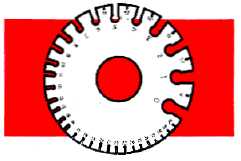

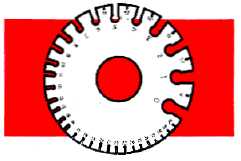

WIRE GAGES

A wire gage is circular in shape with cutouts in the

outside edge. Each cutout gages a different size wire,

from 0 to 36 of the English Standard Wire Gage. A

separate gage is used for American standard wire and

another for U.S. Standard sheet and plate iron, and

steel.

Similar gages are also used to check the size of hot and

cold rolled steel, sheet and plate iron, and music wire.

16-4