TM 9-4940-421-14

INTRODUCTION

S e c t i o n I. GENERAL

PREVENT ENEMY USE. Refer to TM 750-244-3,

the personnel to whom the Shop Set Model SECM,

Procedures for Destruction of Equipment to Prevent

Serial No. Range SECM 1001 thru SECM 2532 is

Enemy Use for destruction of the equipment.

issued.

Equipment maintenance forms and procedures for

MENT RECOMMENDATIONS (EIR) EIR's will be

their use are contained in TM 38-750, The Army Main-

prepared on DA Form 2407, Maintenance Request In-

tenance Management System (TAMMS).

structions for preparing EIR's are provided in TM

38-750, The Army Maintenance Management System

(TAMMS). EIR's should be mailed directly to Com-

740-90-1 for administrative storage of this equipment.

mander, U. S. Army Armament Materiel Readiness

Command, ATTN DRSAR-MAO, Rock Island, Il.

TERIA (ESC). This equipment is not covered by an

61201. A reply will be furnished directly to you.

ESC.

Section II. DESCRIPTION AND DATA

tor-welder is driven by a 154 cu., in., 4 cycle, gas

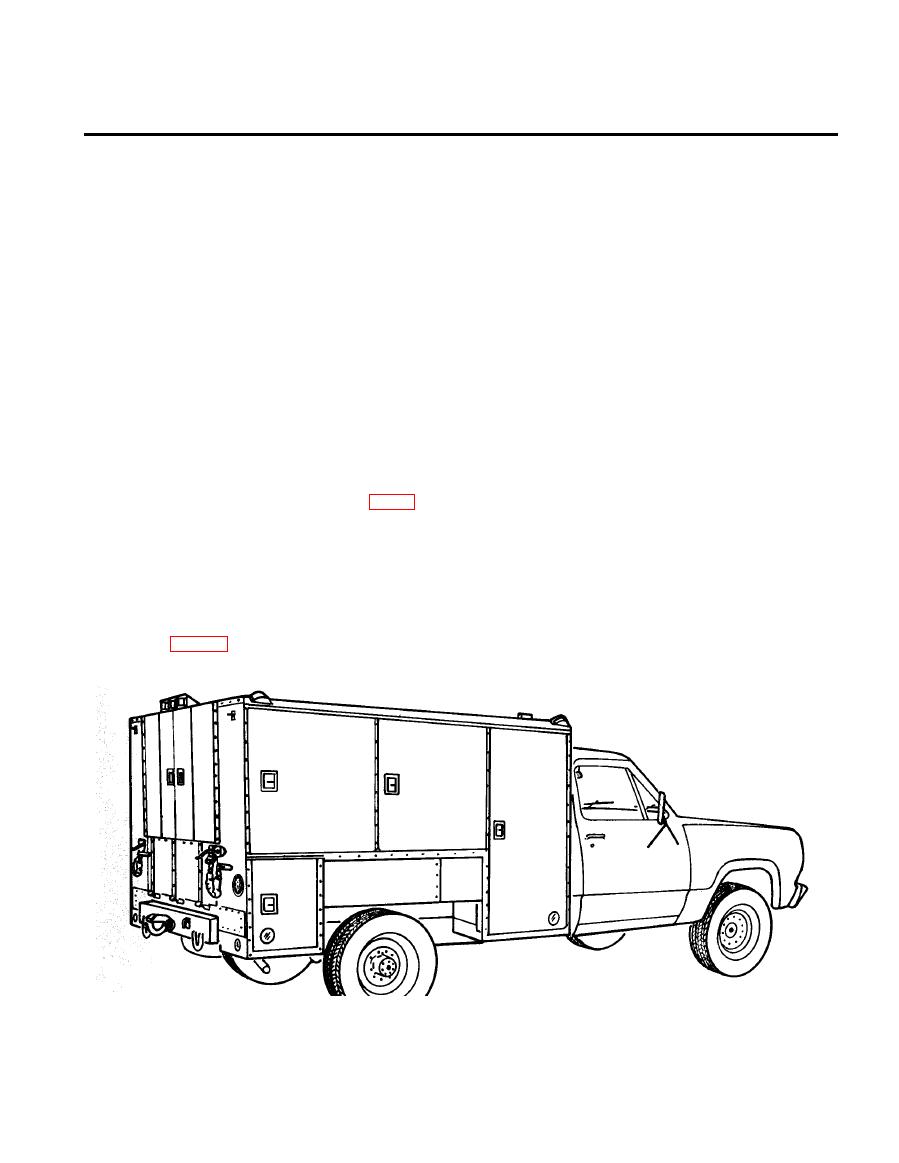

Serial No. SECM 1001 thru SECM 2532 (fig 1-1 and

engine.

1-2), consists of 8 compartments The compartments

NOTE

provide storage space for all tools and equipment. The

This shop set has been designed to operate at temperatures

of -25 F to + 105 F. It can be safely stored at -50 F to

shop set is mounted on a 4x4 Cab/Truck chassis Model

+ 150 F. A suitable arctic kit(s) is under construction for

XM887. The shop is equipped with a generator-welder

shop sets to be used in temperatures colder than those cited

which provides 115 volt single phase alternating cur-

above. If these kits are required, contact Commander, U. S.

rent for operation of the air compressor and other

Army Armament Materiel Readiness Command, ATTN:

DRSAR-MA, Rock Island, Il. 61201.

equipment, and 200 amperes, 28 volt direct current for

welding (see fig FO-1 for wiring diagram). The genera-

AR 701532