in the table legs. Secure each table with six 5 / 16-

diameter flat washers 5310-760-2021, two 7/16-

18 x 2 - inch hexagon-head machine bolts 5305-

inch split lockwashers 5310-905-5454, and two

225-8504, six 7/16-inch hole diameter rect-

7/16-20 hexagon plain nuts 5310-741-5305.

angular flat washers 5310-209-0061 (place on

(4) Secure nitrogen tank (designated F ) to

underside of floor), six 11/32-inch inside diameter

blocks with webbing straps. Fabricate straps using

flat washers 5310-081-4219, six 5/16-inch split

webbing 8305-263-2477 and buckles 5340-850-

lockwasher, 5310-407-9566, and six 5 / 16-18

8060. Position and secure strap fastener loops

hexagon plain nuts 5310-880-7744

5340-616-4660 at opposite ends of each block with

two No. 10-2-1/2 inch round head wood screws

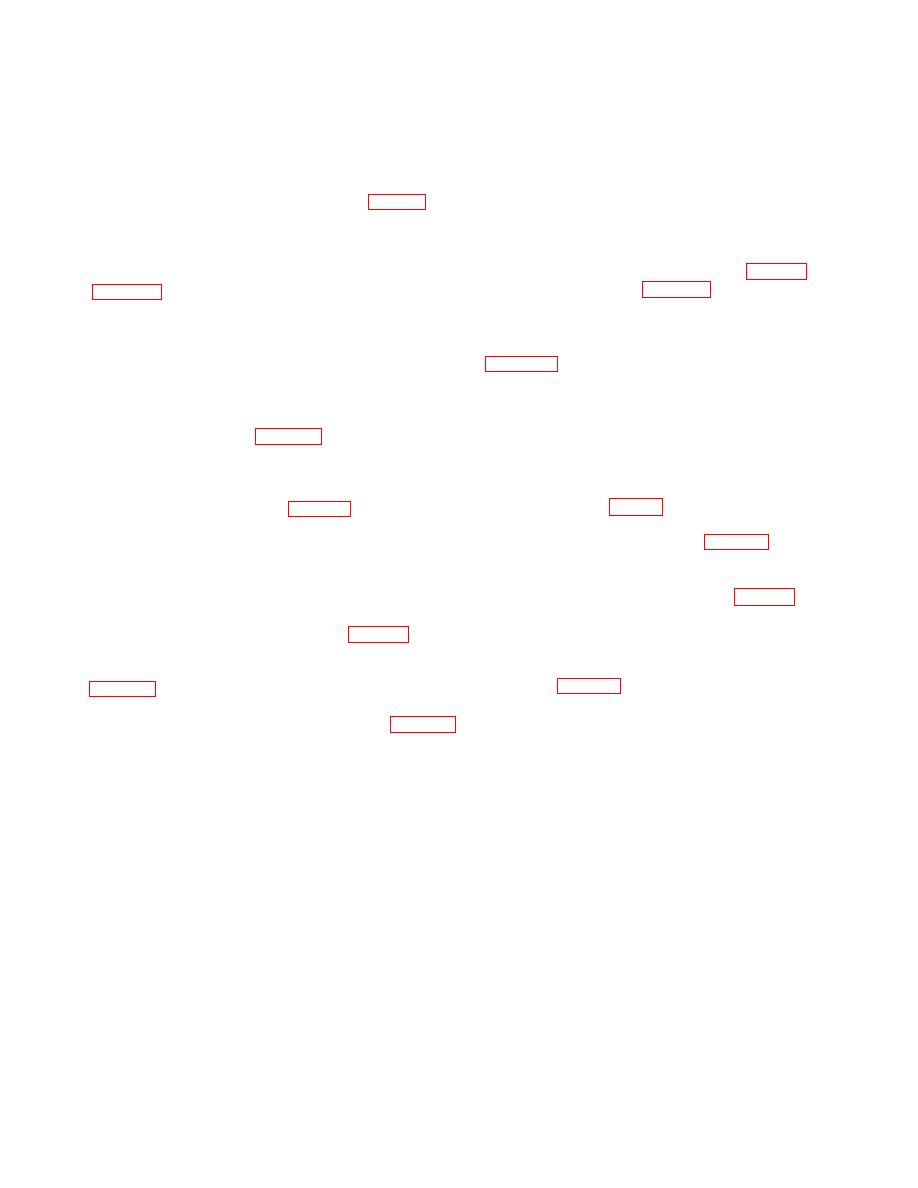

6. Portable Electric Drill with Stand (Figs. 2 and

5305-013-0384 and two .234 inch inside diameter

3). Place the drill with stand 5130-204-2718

flat washers 5310-273-7729. Loop webbing straps

(designated A ) on work table (B), and position the

through fastener loops and buckle as required to

base of the stand 10 inches from the left end of the

hold tank firmly in place as shown in figure 4.

table top and 1 inch from the front edge as shown in

e. Generator Set (Figs. 2 and 4). Place the

generator set 6115-889-1446 (Designated G) on

through the table top aligned with the mounting

the floor of the truck, two inches from the left side

holes in the base of the stand. Secure the drill and

of truck and flush against table (I) as shown in

stand with three 3/8-24 x 2-1/2-inch hexagon-head

cap screw 5305-269-3244, six 25/64-inch inside

legs with webbing straps which are to be fabricated

diameter flat washers 5310-167-0804, three 3/8-

using webbing 8305-263-2477 and a buckle 5340-

inch split lockwashers 5310-737-4728, and three

3/8-24 hexagon plain nuts 5310-975-2075.

850-8060.

CAUTION: The generator set is secured in

c. Machinist's Vise (Figs. 2 and 3). Place the

the cargo truck for transportation purposes

machinist vise 5120-293-1439 (designated D) on

only and is to be removed from the truck

work table (C), and position the base of the stand 4

before operation.

inches from the right end of the table top and flush

f. Pump Kits (Fig. 4). Place the two pump kits

with front edge as shown in figure 2. Mark and drill

4933-712-2378 (designated H) on the lower shelf

four 9/16-inch holes in the base of the vise. Secure

of work table (C) as shown in figure 3. Secure the

the vise with four 1/2-13 x 3 1/2-inch square neck

kits to the shelves with fabricated webbing straps as

bolts 5306-702-2821, four 17/32-inch inside

required.

diameter flat washers 5310-809-5998, four 1/2-inch

g. Portable Electrical Grinder (Figs. 2 and 4).

split lockwashers 5310-584-5272, and four 1/2-13

Place the portable electrical grinder 5130-293-

hexagon plain nuts 5310-834-8732.

2488 (designated J) on work table (I) and position

d. Nitrogen Tank Support Block (Figs. 2, 4 and

the base of the grinder 10 inches from the right end

5).

and 2 inches from the front edge of the table top as

(1) Fabricate two support blocks as shown in

shown in figure 2. Mark and drill four 11/32-inch

holes through the table top aligned with mounting

two bow stake tubes and are to be placed on the left

holes in the base of the grinder. Secure the grinder

side of the truck at the rear as shown in figures 2

with four 5/16-18 x 2 1/2-inch square neck bolts

and 4.

5306-058-0518, four 11/32-inch inside diameter

(2) One block is to span the rear two bow stake

flat washers 5310-081-4219, four 5/16-inch split

tubes, even with the top side rack slat. Mark and

lockwashers 5310-407-9566, and four 5/16-18

drill, at each end of block, 1/2-inch holes through

hexagon plain nuts 5310-880-7744.

block, bow stakes and bow stake tubes. Secure

6. Reporting of Equipment Publications

block with two 7/16-20 x 8-inch hexagon-head

Improvements.

The reporting of errors,

machine bolts 5306-027-5803, two 1/2-inch inside

omissions, and recommendations for improving this

diameter flat washers 5310-760-2021, two 7/16-

publication by the individual user is encouraged.

inch split lockwashers 5310-905-5454, and two

Reports should be submitted on DA Form 2028

7/16-20 hexagon plain nuts 5310-741-5305.

(Recommended Changes to DA Publications).

(3) The other block is to be placed midway

Forward completed forms direct to: Commanding

between the floor and the top of the permanent

General, Headquarters, U . S . A r m y W e a p o n s

side. Mark and drill, at each end of block, 1/2-inch

Command, ATTN: AMSWE-SMM-P, Rock

holes through block and side of truck. Secure block

Island, IL 61201.

with two 7/16-20 x 5-1/2-inch hexagon-head

machine bolts 5306-177-5677, two 1/2-inch inside

5