TM 1-4920-433-13&P

FIELD MAINTENANCE

PNEUDRAULIC SHOP

MAINTENANCE INSTRUCTIONS FOR CABINET ASSEMBLIES

INITIAL SETUP:

Personnel Required

Tools and Special Tools

CMF 44-B Metal Worker (1)

Drill Set, Twist (WP 0062 00, Table 2, Item 102 )

CMF 15 Series (3)

General Mechanics Tool Kit

References

(WP 0062 00, Table 2, Item 104 )

Paint Brush (WP 0062 00, Table 2, Item 107 )

Portable Electric Drill (WP 0062 00, Table 2, Item 108 )

TM 1-1500-204-23

Materials/Parts

Equipment Condition

Enamel, Gray (WP 0069 00, Item 2)

Functional

NOTE

During installation of components same hardware should be used so as to maintain original

integrity of shop set.

REMOVAL

KICK PLATE

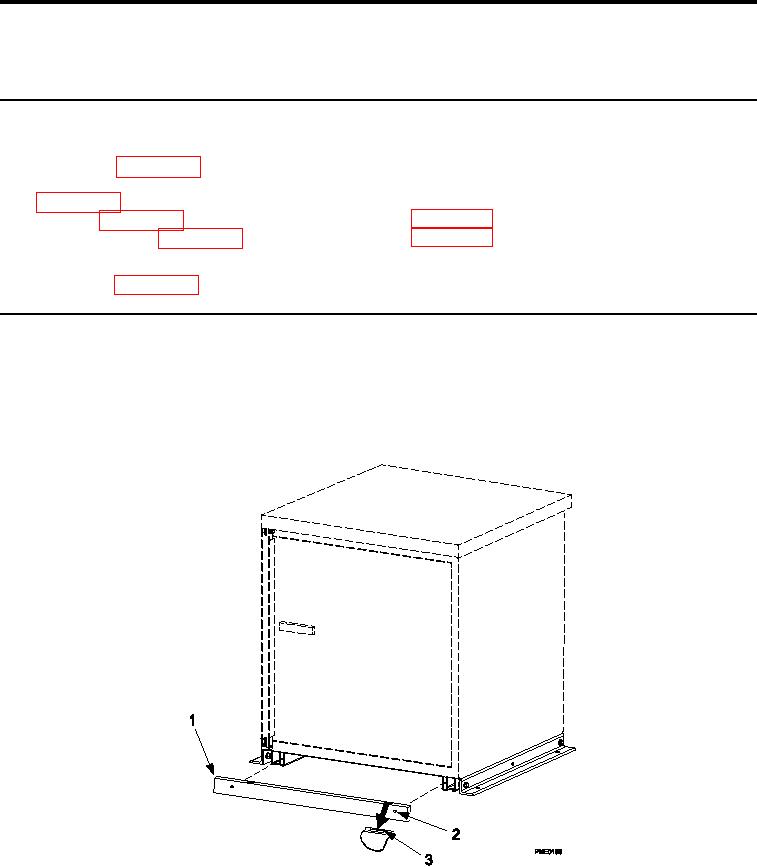

Figure 1.

Kick Plate Remove and Install.

1.

Wedge screwdriver at indentation (Figure 1, Item 3) on each side of kick plate (Figure 1, Item 1).

2.

With screwdriver, pull kick plate (Figure 1, Item 1) outward on each side. Kick plate (Figure 1, Item 1) should

easily dislodge from cabinet.

0036 00-1