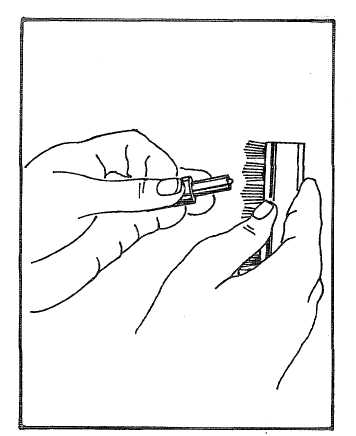

Figure 6-21. Cleaning the Nozzle Tip

results, Start with a cleaning wire of.008 -

.010 Inch (0.20 ± 0.003 mm) and .010 inch

(.028 mm) for final cleaning. Clean the sac

hole with a .051 Inch (1.3 mm) diameter

drill. See Figure 6-22.

(5)

Clean the valve seat area with a special

brass scraper tool. Use cleaning tallow on

the end of a 2.inch (50 mm) cleaning stick

to polish the seat. Use a sac hole drill to

push the tallow through the orifices. All

openings must be open and clean, See

Figure 6-23.

(6)

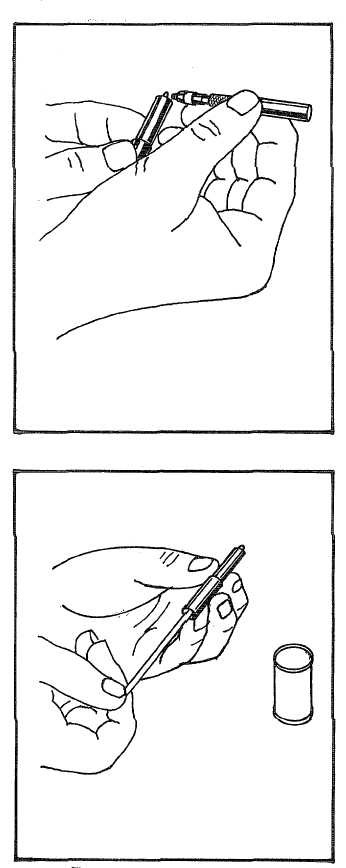

Gum deposits may be removed with a

brass wire brush, The upper portion (large

diameter) of the valve should not be held

between the finger, since damage from

corrosion could re-suit, See Figure 6-24.

c.

Refer to paragraph 6-3.b for general in-spection

instructions.

(1)

Using a magnifier, inspect the mating

surfaces

of

the

nozzle

components,

particularly the intermediate plate (5) and

nozzle (6) for nicks, scratches or signs of

corrosion. Failure of these

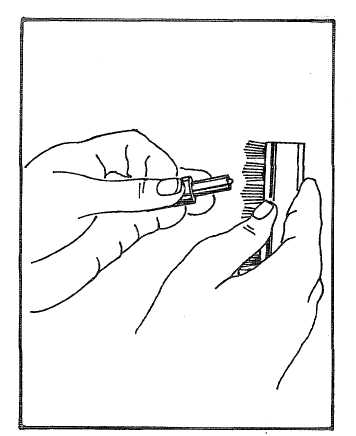

Figure 6-23. Cleaning Nozzle and Seat

6-60

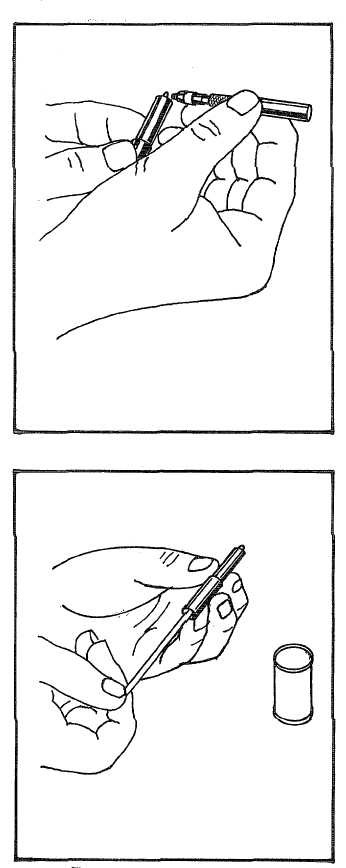

Figure 6-22. Cleaning the Orifice Holes