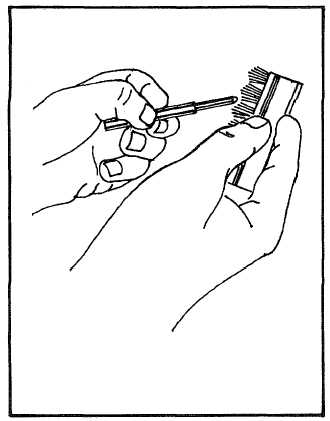

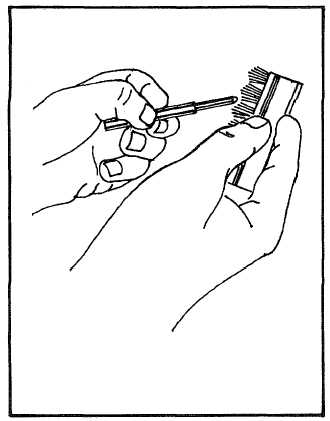

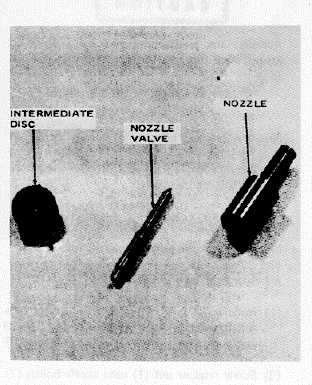

Figure 6-24. Cleaning Nozzle Valve

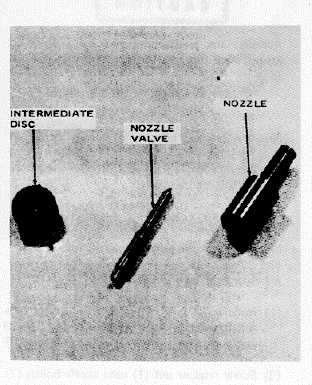

surfaces to seal properly will result in leakage to the

return or to the outside of the nozzle. See Figure 6-25.

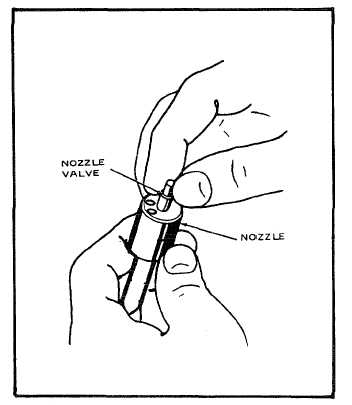

(2)

Inspect the retainer nut (7) for cracks and

re-place it if damaged.

(3)

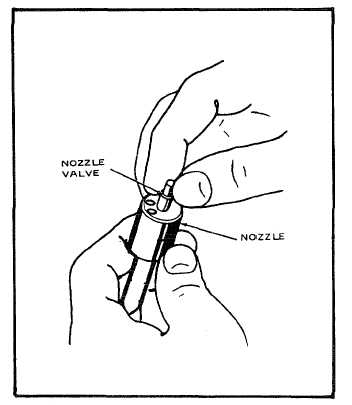

Check the stem and the body of the nozzle.

When both parts are wet with fuel oil, no sticking should

be evident. Pull the valve out of the nozzle about one-

third of its length. When released, the valve should slide

freely back to the seat. Foreign matter or scratches on

the valve will cause it to stick. Carefully inspect before

installing the valve. See Figure 6-26.

d.

Repair or Replacement. Refer to paragraph 6-

3.c for general repair or replacement instructions.

(1)

If necessary, recondition nozzle and inter-

mediate disc surfaces by lapping.

(2)

Replace all threaded parts having worn,

stripped or damaged threads.

c.

Assembly. To assemble the fuel injector

assembly, proceed as follows:

Figure 6-25. Inspecting Mating Surfaces

Figure 6-26. Checking Freedom of Valve in Nozzle

6-61