(6)

Remove elbows (I 7) from cylinder (19, 22,

23, 24 and 25). Unscrew and remove

priority valve (20) and nipple (21) from

cylinder (22). Unscrew and remove the ten-

micron filter (29) and adapter (27) from

cylinder (25).

b.

Cleaning. Refer to paragraph (6-3.a for general

cleaning instructions.

c.

Inspection. Refer to paragraph 6-3.b for general

inspection

requirements.

Specific

assembly

inspection/testing as follows.

(1)

Test the priority valve (20, Figure 8-2)

as follows:

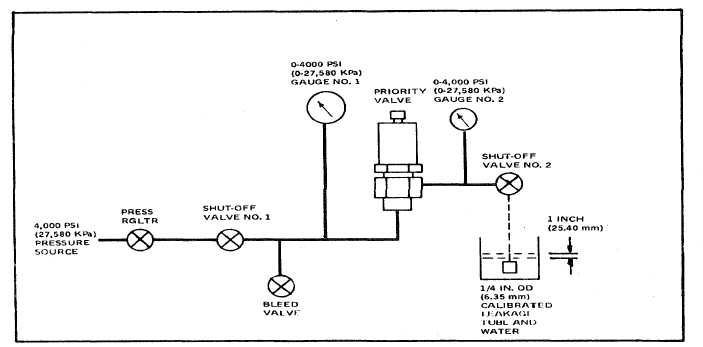

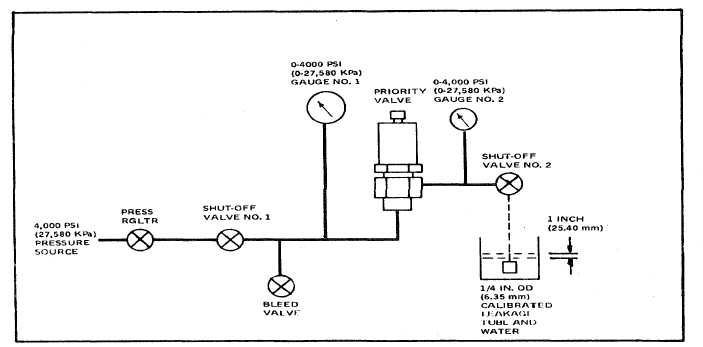

(a)

Screw a 1/8 npt pipe plug in one

side of valve body (12. Figure 8-5). Install priority valve

to be tested in test setup shown in Figure 0-3, or

equivalent.

NOTE

Hydrostatic tester may be used in lieu of air or

nitrogen.

(b)

Close bleed valve and open shut-off valves.

numbers one and two.

(c)

Adjust regulator, increasing pressure to tile

inlet side of the priority valve assembly

under test, until air escapes from priority

valve outlet port.

NOTE

Gauge should indicate 2,200 + I00 psi (5,158 + 690

KPa). If indication is correct, proceed to step (g).

Otherwise, proceed with step (d).

(d)

Remove priority valve assembly from test

setup if specified limit is not obtained as

specified in step (c) of this paragraph.

(e)

Rotate adjusting screw (2, Figure 8-5) in or

out as may be required.

(f)

Re-install priority valve assembly in test

setup and repeat steps (a) through (c). Re

peat steps (d) and (e) until

desired

indication is obtained.

(g)

Close shut-off valve number two (Figure 6-

3) and remove leakage apparatus.

Figure 6-3. Priority Valve Test Setup

6-5