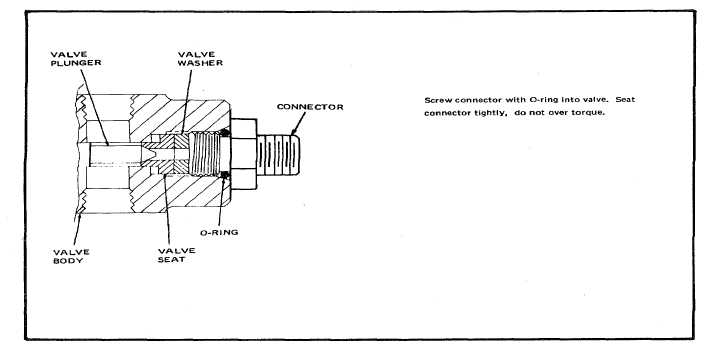

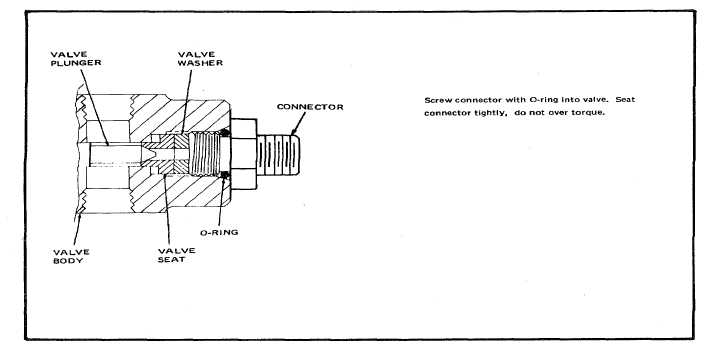

Figure 6-4. Seating Priority Valve Connector.

(1)

Unscrew and remove head (5) from bowl

(1).

(2)

Remove element (2) from bowl (1).

(3)

Remove two backup rings (3), and o-ring

(4) from filter head (5).

b.

Cleaning. Refer to paragraph 6-3.a. for general

cleaning instructions.

(1)

Flush the filter bowl clean with P-D-680,

Type II, or equivalent.

(2)

Clean the filter head with the flushing agent.

(3)

Allow bowl and head to air dry until odor of

the flushing agent disappears.

c.

Inspection. Refer to paragraph 6-3.b. for

general inspection instructions.

d.

Repair or Replacement. Minor nicks, scoring, or

scratches on filter body surface may be smoothed with

crocus cloth, per Federal Specification P-C-589. Clean

up minor thread damage to threaded connections. The

repair and replacement procedure for the ten micron air

filter assembly is as follows:

(1)

Replace all threaded parts having worn,

stripped, or damaged threads.

(2)

Replace all parts that are worn or damaged

to an extent that will impair their normal

function.

e.

Assembly. To assemble the ten-micron filter

assembly (Figure 8-6), proceed as follows:

(1)

Assemble the two backup rings (3) and o-

ring (4) on filter head (5).

(2)

Place filter element (2) in position and

screw filter head (5) onto bowl (1).

6-10.

Control Panel Group (See Figure 8-7). To

remove the control panel group from the air compressor

unit, see Figure 8-7, 8-8, 8-10, and 8-11 and proceed as

follows:

a.

Disassembly. Control panel group (see Figure

8-7) and proceed as follows:

(1)

Disconnect cylinder 1 to 1st stage cooler

hose assembly (1, Figure 8-39) at elbow

(21, Figure 8-11). Unscrew 1st stage

cooler to 1st stage trap tube assembly (2,

Figure 8-39) al elbow (22, Figure 8-10).

6-9