TM 5-4310-381-13

SECTION III. TECHNICAL PRINCIPLES OF OPERATION

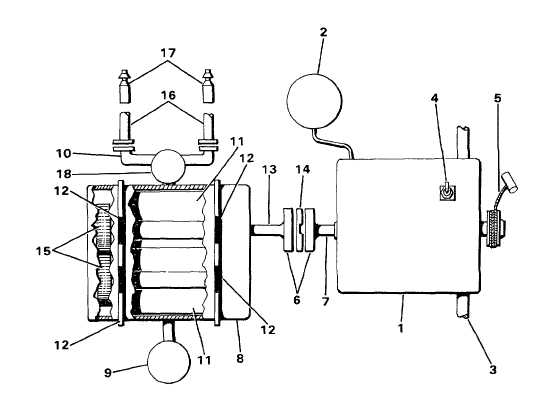

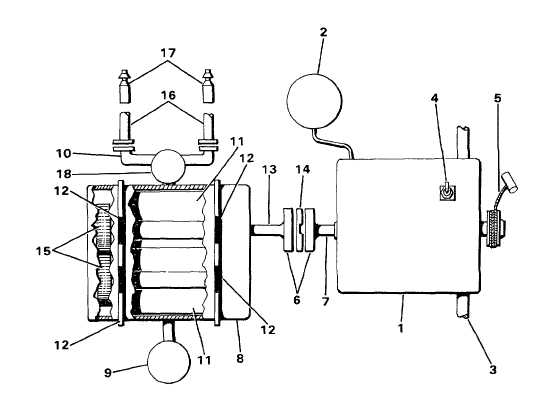

1-13. OPERATION OF THE AIR COMPRESSOR.

1.

GAS ENGINE

10. OUTLET TEE

2.

FUEL TANK

11. IMPELLERS

3.

ENGINE AIR FILTER

12. BEARINGS

4.

ON/OFF SWITCH

13. DRIVE SHAFT

5.

ROPE STARTER

14. NEOPRENE INSERT

6.

COUPLING

15. TIMING GEARS

7.

CRANKSHAFT

16. AIR HOSES

8.

AIR PUMP

17. INFLATOR VALVE

9.

PUMP AIR FILTER

18. SAFETY VALVE

Compressor Operation

a. Gas Engine (1). Draws gas from the frame-mounted tank (2) and air through its own air filter (3). Controlled by an

ON/OFF switch (4) and started by a pull rope starter (5). Through use of piston, connecting rods, and crankshaft,

produces 3 hp. Connected to the air pump through a coupling (6) mounted on engine crankshaft (7).

b

Air Pump (8). Rotary impellers compress air taken in through the pump air filter (9) and forces air out through the

outlet tee (10). Impellers (11 ) are mounted on shafts of unequal length and supported by bearings (12) on both ends.

Longer shaft serves as the drive shaft (13) and is connected to the engine through coupling (6) and a neoprene insert

(14). Impellers are held in proper time by timing gears (15) mounted on opposite ends of drive shafts.

c. Safety Valve (18). A safety valve with relief setting of 6.5 psi prevents pressure buildup in the air pump and hoses.

d. Air Hoses (16). Two 25 ft. hoses are stored on the frame for transport. Quickly connected to outlet tee (10) to

provide air to the inflator valve assemblies (17). Assemblies are specially designed for inflating ponton floats.

1-6