f. Grounding Shop Set. Drive a metal ground rod

frequency of the incoming current, as shown by the

into the ground adjacent to the shop set. Attach a

frequency meter, either 50 or 60 cycles, and set the

No. 6 bare copper wire between the shop set ground

power selector switch on CITY. Conversion to shop

terminal (fig. 2-9 ) and the ground rod.

set generated power is accomplished by stopping all

shop set functions, turning switches to OFF and by

WARNING

removal of the external power source, setting the

Static electricity and leakage currents

from electric equipment can build up in

frequency switch to desired frequency output,

the chop set and cause injury or death to

either 50 or 60 cycles, and the power selector switch

personnel unless the equipment is

to GENERATOR. The output from the receptacles

properly grounded.

on the control panel is either 120-volt, single-phase,

at a maximum of 15 amperes, or 240-volts, single-

2-3. Equipment Conversation

phase, at a maximum of 10 amperes. To use either

The d ynamotor-welder can be driven by the truck's

120 or 240-volts from either GENERATOR or

engine through the power take off or by a 240-volt

CITY power source, select the appropriate output

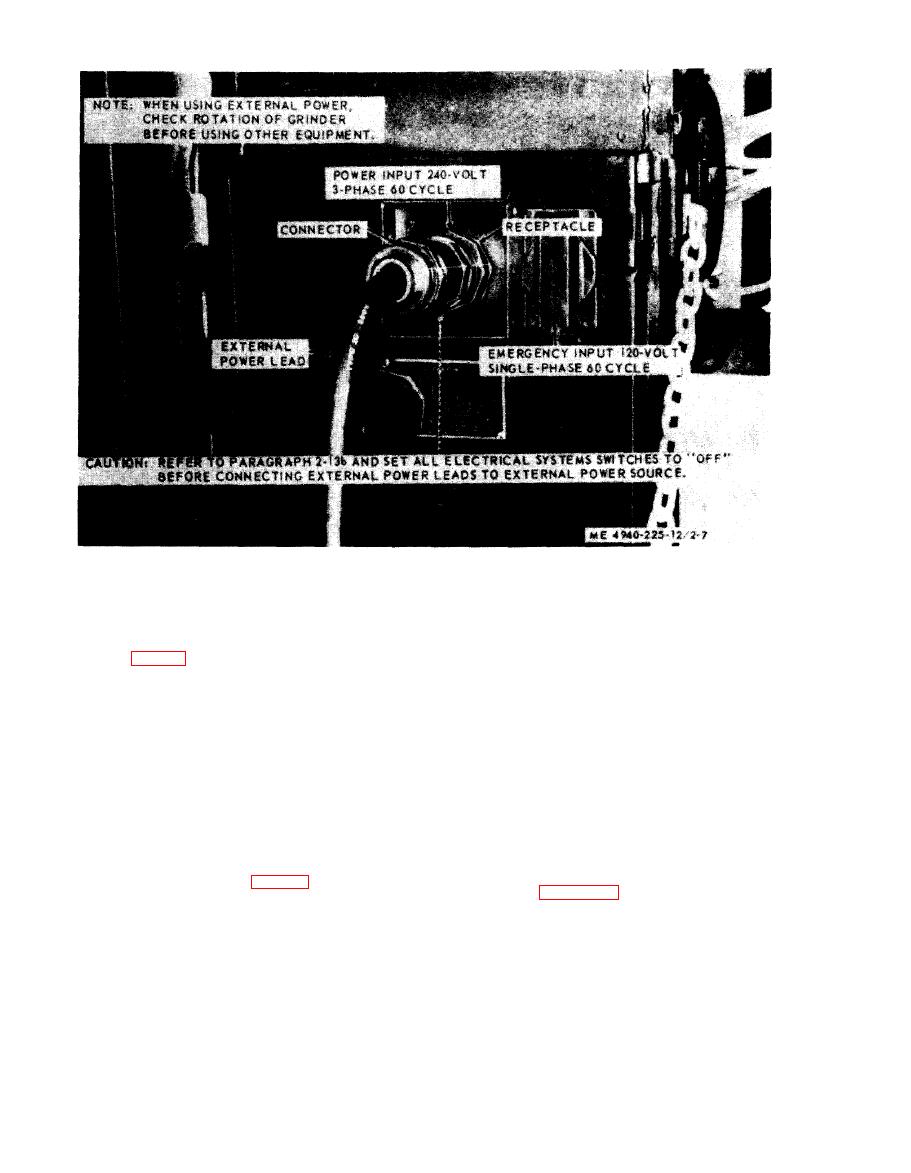

AC external power source. If an external power

receptacle or receptacles and the applicable power

source is to be used, connect the power source and

selector switch and frequency switch setting as

set the frequency switch (fig. 2-8) to match the

indicated in figure 2-8.