TM 55-4920-217-15

the operator should be alert for any unusual noises,

32. Specific Procedures for Operator

vibrations, or irregularities of performance.

d. At Halt Service. This service will consist of brief

visual inspection of equipment for condition, security,

on the shop set by the operator in the procedure

and wear; the removal of foreign material from

opposite it should be performed during that part of the

equipment; and the cleaning of equipment that might be

daily service in which it appears.

damaged by allowing existing conditions to continue.

e. After Operation Service. This service consists

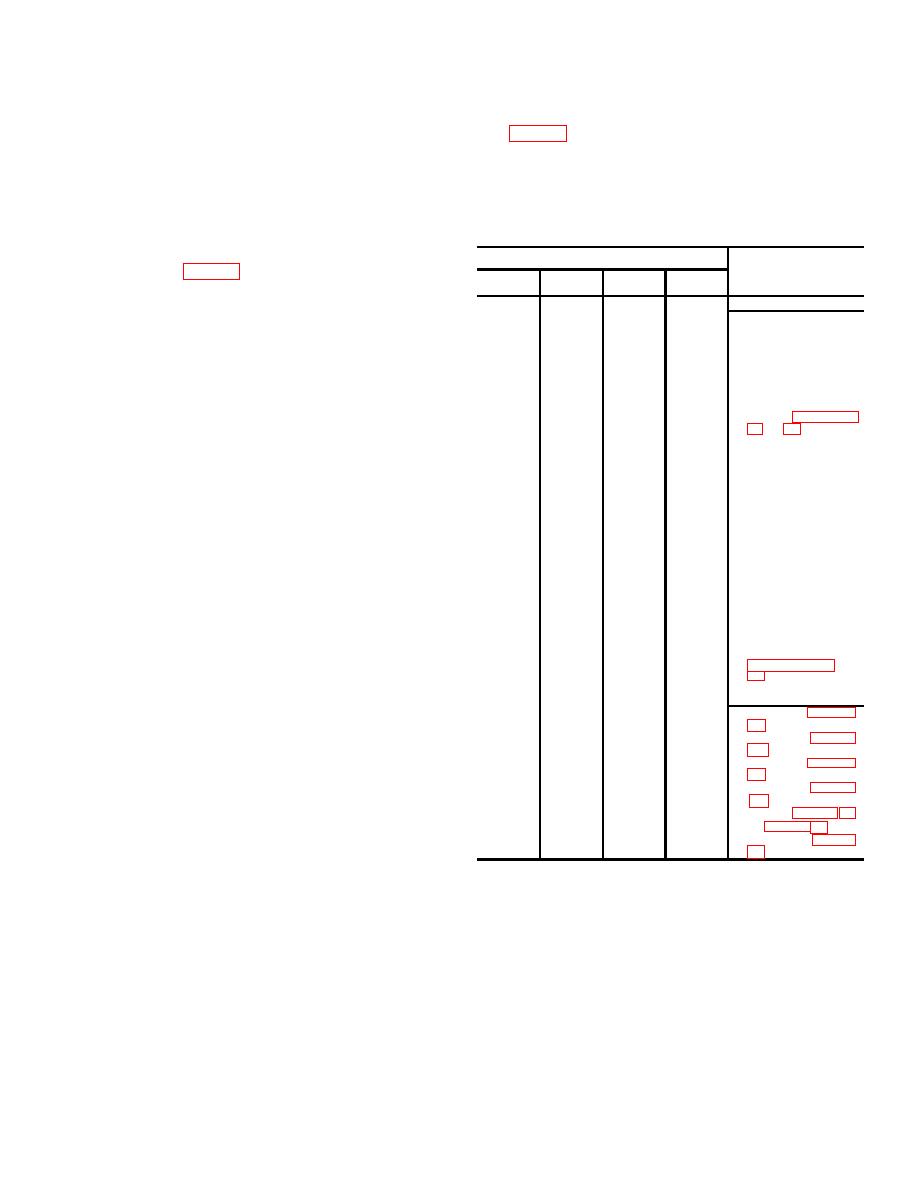

Table I. Operator Daily Service

of investigating any deficiencies noted during operation

and performing certain phases of the before operation

Intervals

service as noted in Table I. It is the basic daily service

Before

During

After

Procedure

At Halt

for equipment and consists of correcting, insofar as

operation

Operation

Operation

Usual conditions

possible, any operating deficiencies; in this manner, the

Visual

Inspection

of

X

----

X

X

equipment is prepared to operate upon short notice.

Equipment. Inspect for

f. Inspection. The general inspection of each item

condition, security and

wear.

is generally a check to see whether the item is in good

Cleaning of Equipment.

X

condition, correctly assembled, secure, and not

Wipe dirt, oil rust,

excessively worn.

corrosion, and debris

from

equipment.

g. Definition of Terms. Terms used to describe the

Refer to paragraphs

inspection requirements of this section are defined as

instructions.

follows:

Operating Units. Check

X

----

X

X

(1) Good condition.

This

is usually an

all units for correct

external inspection to determine whether

assembly and loose

mounting. Adjust as

the unit is damaged beyond serviceable

necessary.

limits.

The term "good condition"' is

Power Supplies. Check

X

----

----

X

for loose power supply

explained further by the following; Not

connections; check for

bent or twisted, not chafed or burned, not

frayed

or

cracked

broken or cracked, not bare or frayed, not

insulation.

Operation. While equip-

X

----

dented or collapsed, not torn or cut, not

ment is operating,

deteriorated.

check for unusual

sounds, vibrations, or

(2) Correctly assembled. This term refers to

malfunction.

the inspection of a unit to see that it is in

Lubrication.

Lubricate

X

----

----

X

the normal assembled position. It is

in accordance with

para- graphs 29, and

usually an external visual inspection.

(3) Secure. This is usually an external visual

Unusual Conditions

inspection or check by hand or wrench for

X

X

X

X

looseness. Such an examination must

include any rackets, lock washers, lock

X

X

X

X

nuts, locking wires, or cotter pins used.

X

----

X

X

(4) Excessively torn. This inspection is to

X

X

X

X

determine whether equipment is worn

beyond serviceable limits or to a point

X

----

X

X

likely to result in failure if the unit is not

X

----

X

X

X

X

X

X

replaced before the next scheduled

inspection.

14