TM 9-243

TYPES AND USES

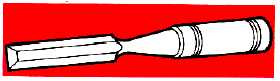

WOODWORKER'S CHISELS

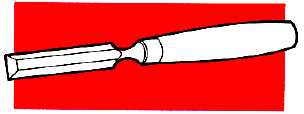

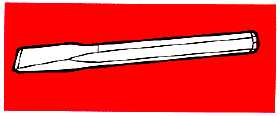

There are two types of woodworker's chisels. The

socket type has a blade and socket handle forged of

high carbon steel in a single casting. The wooden

handle is inserted into the socket. This type of chisel is

used to cut and pare off wood. Generally socket-type

chisels are used for heavier cutting when a hammer or

mallet may be required for additional driving force.

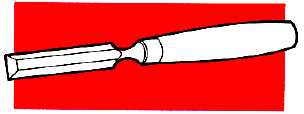

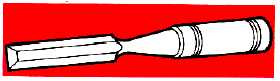

The tang-type chisel is forged in a single casting. The

handle is drilled and inserted over the tang and

reinforced with a metal band. The tang-type chisels are

also used to cut and pare wood. However, the driving

force required is hand pressure only.

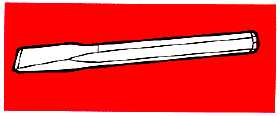

MACHINIST'S CHISELS

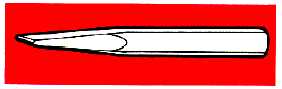

Machinist's chisels are designed to cut and shape cold

metal and are usually struck with a hammer. The flat or

cold chisel is composed of hardened steel and has a

tapered cutting edge on one end and a flat base on the

other end.

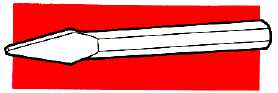

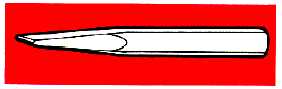

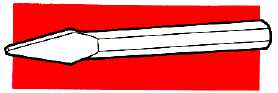

The diamond point chisel has a solid point on one end

and a flat base on the other end. It is used for drawing

and cutting holes in flat stocks and to cut V-grooves.

The cape chisel has a small solid point on one end and

a flat base on the other end. It is used for cutting

keyways or slots in metal, and square corners.

The roundnose chisel has a ground edge on one end

and a flat base on the other end and an octagon-shaped

stock. It is used to align drilled holes, cut channels, cut

oil grooves and similar work.

TRACK CHISEL

The track chisel has a beveled point on one edge and a

flat face on the other end. The cutting edge is 1-3/8

inches wide; the overall length is 10-1/2 inches and it

weighs 5-1/2 pounds. The track chisel is used with a 22-

inch sledge hammer to remove track bolts, boiler rivet

heads and cut rail when a saw or cutting torch is not

available.

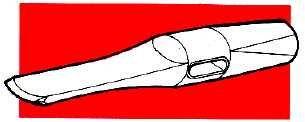

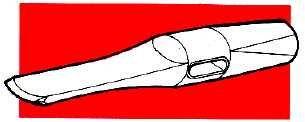

RIVET BUSTER CHISEL

The rivet buster chisel has a single ground flat cutting

edge on one end and a flat face on the other end. The

cutting edge is about 3/4 inch wide and the overall

length is about 9 inches. It is used for cutting off chassis

rivets and in other difficult places which cannot be

reached by other chisels.

26-2