TM 9-243

SOLDERING

Soldering that will meet Air Force requirements of no

more than 1 error out of each 500,000 soldered

connections requires skilled application and integrity.

The success of IBM's reliability factor may depend on a

satisfactory soldered connection. Consider this down-

time comparison. The time spent to find a defective

tube, resistor, transformer, or other component part

averages half an hour. Isolating a poor soldered

connection can take eight hours or longer.

Solder is one of the oldest and most useful of alloys.

Because of the ease with which it has been used, few

people have bothered to acquire the basic, but

necessary, background for good soldering techniques.

Soft solder is a fusible alloy mainly composed of tin and

lead.. This alloy makes it possible to join two or more

metals at temperatures well below their melting point.

The solder-to metal attachment is formed by an inter

metallic

compound

phase

which

takes

place

at

comparatively low temperatures . The solvent action of

hot solder on copper or steel resembles the action of a

few drops of water on salt. The solder dissolves

microscopic particles of the copper or steel, forming a

chemical attachment instead of physical adhesion.

Therefore, heating the soft flexible solder during the

soldering act causes a chemical change to take place

which results in a hard metal alloy. Thus when two or

more pieces of metal are soldered together, a joint is

formed which acts like one continuous piece of metal.

(This is not true of a pure physical connection, such as a

bolt or spring, because a layer of oxides always remains

between he surfaces.) In addition, the solder alloy

withstands the stress and strain of the temperature

changes without rupture of the joint.

The primary purpose of a soldered joint is to achieve an

airtight metallic connection by means of a film of solder

alloy, varying in thickness from 0.002 to 0.004 inch

between the metal parts; i.e., wire and terminal. When

such a connection has been made, It is a waste of time

and material to add solder just to improve its

appearance;

the

electrical

conductivity

has

been

established with the original bond and will be unaffected

by the addition of solder.

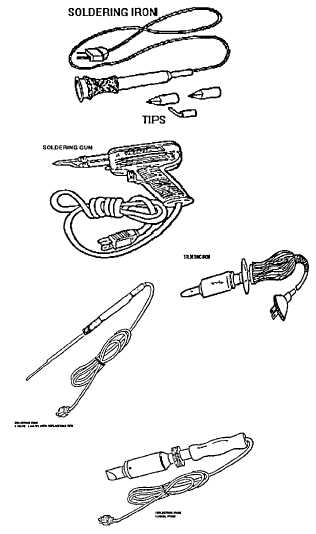

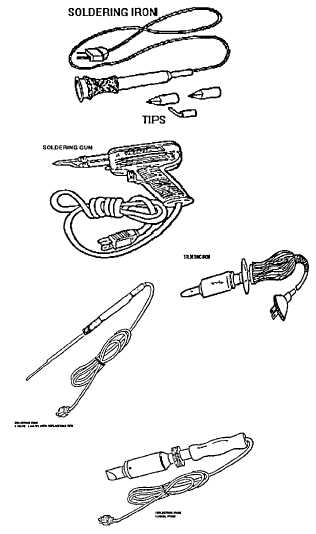

SOLDERING TOOLS

Five different soldering irons with interchangeable tips,

transformers (6.3 VAC), heat shunts, soldering iron

holders, soldering aids, and electric solder pot comprise

the soldering tools stocked at field locations. The

6.3VAC soldering irons are to be used with the

transformer which has four wattage tips: 26, 29, and 35.

Always use the lowest wattage necessary for the work.

In most cases 26 watts will be sufficient for electrical

soldering.

53-8 Change 3