TM 1-4920-441-13&P

FIELD MAINTENANCE

TOOL CRIB SHOP

MAINTENANCE INSTRUCTIONS FOR EYEWASH STATION ASSEMBLY BRACKET AND HARDWARE

INITIAL SETUP:

Tools and Special Tools

Personnel Required

CMF 15 Series (2)

General Mechanics Tool Kit

(WP 0059 00, Table 2, Item 104 )

References

Torque Wrench, 0-600 in. lbs.

Sperian Fendall Pure Flow 1000 Eyewash Station

(WP 0059 00, Table 2, Item 109 )

Owner s Manual

Materials/Parts

Equipment Condition

Eyewash Station Removed

Fountain, Eye and Face Wash (WP 0066 00, Item 4)

INSPECTION OF INSTALLED ITEMS

NOTE

During installation of components same hardware should be used so as to maintain original

integrity of shop set.

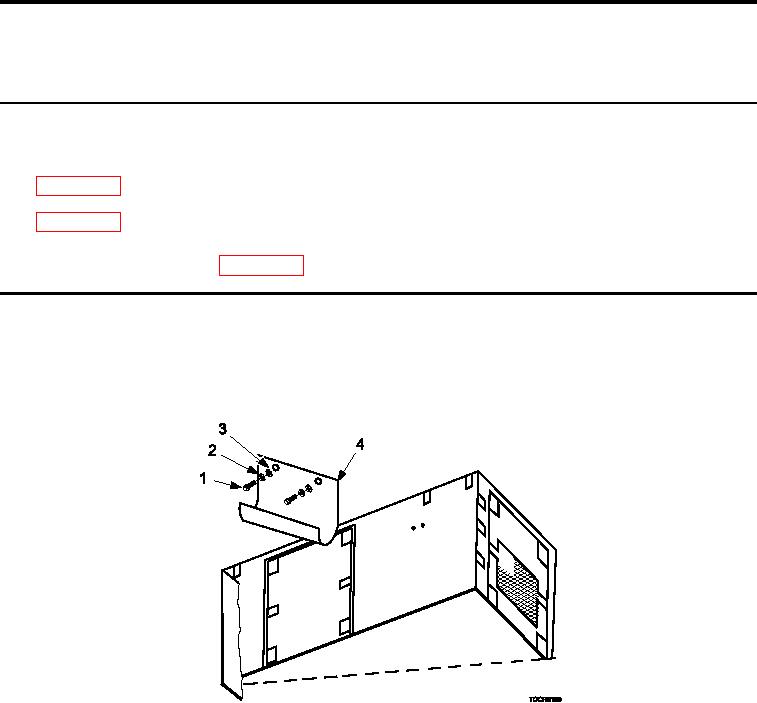

Figure 1.

Eyewash Station.

1.

Inspect eyewash station bracket (Figure 1, Item 4) for damage. Replace as necessary.

2.

Inspect eyewash station bracket hardware (Figure 1, Item 1 through 3) for rust, cracks and rounded heads.

Replace as necessary.

REMOVAL

1.

If necessary, drain eye and face wash fountain solution IAW with Sperian Fendall Pure Flow 1000 Eyewash

Station Owner s Manual.

2.

Remove two bolts (Figure 1, Item 1), two lock washers (Figure 1, Item 2), two lat washers (Figure 1, Item 3),

and eyewash station bracket (Figure 1, Item 4).

INSTALLATION

1.

Position eyewash station bracket (Figure 1, Item 4) by aligning bolt holes with wall inserts.

0042 00-1