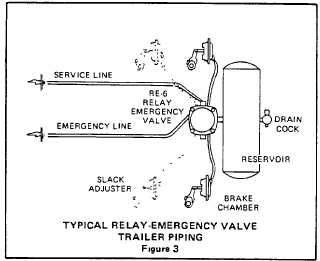

Figure 3.

EMERGENCY APPLICATION

(Trailer Air System charged to normal operating

pressure) Venting the trailer supply line to atmosphere

will cause the emergency portion of the Relay

Emergency Valve to apply full trailer reservoir pressure

to the trailer air chambers if the trailer supply line

pressure is reduced to approximately 20 psi due to

leakage or conditions other than above, a graduated

trailer air chamber application will occur. The rate of this

brake application will depend upon the rate of pressure

loss in the supply line

If the trailer is not equipped with parking actuators (such

as spring brakes), the trailer wheels should be blocked to

prevent trailer movement, in the event reservoir pressure

would be depleted.

TO RELEASE AN EMERGENCY APPLICATION

Recharge trailer air system or:

A.

For trailers equipped with standard brake chambers,

block wheels and drain trailer reservoir.

B.

For trailers equipped with spring brake chambers,

block wheels and mechanically release spring brake

chambers via the mechanical release mechanism

(for specific instructions, refer to manufacturers

service literature.)

PREVENTIVE MAINTENANCE

Every 12 months, 100, 000 miles or 3600 operating

hours disassemble, clean metal parts in mineral spirits.

Replace all rubber parts and any part worn or damaged.

Check for proper operation before placing vehicle in

service. To prevent entrance of foreign matter, it is

recommended that filters be installed in the trailer supply

and service hose couplings. Check periodically, and

clean or replace as necessary.

OPERATING AND LEAKAGE TEST

Check tractor dash gauge against a test gauge known to

be accurate prior to performing these tests Connect

tractor air lines to the trailer on which the valve is to be

tested. Block wheels or otherwise hold both vehicles by

a means other than air brakes during these tests.

1.

Start these tests with no air pressure in the tractor or

trailer system. Make certain trailer connection cut-

out cocks are open if present Build tractor air system

to at least 50 P.S.I. Move tractor protection control

valve to normal position As trailer system starts to

charge, trailer brakes should apply and then

completely release as trailer supply line pressure

reaches 60-65 P.S.I

2.

Fully charge tractor and trailer air brake system

Make several service brake applications and check

for prompt braking response at all trailer wheels.

With brakes released and system reservoir pressure

stabilized at 100-120 psi with engine stopped, a two

minute check should result in no more than a six

pound pressure drop for the combination vehicle

system. If this check indicates possible excessive

leakage of valve, soap suds should be applied to the

exhaust port to detect possible leakage of inlet valve

and emergency piston O-Ring leakage. Leakage of

a one inch soap bubble in not less than five seconds

is permissible. No leakage is permissible at pipe

plugs or fittings.

3.

Make and hold a full service brake application with

system reservoir pressure stabilized at 100-120 psi

with engine stopped. A two minute check should

result in no more than an eight (8) psi drop for the

combination vehicle system. If this check indicates

possible excessive leakage of valve, soap suds

should be applied to cover to detect body O-Ring

leakage and to exhaust port to detect exhaust valve

and O-Ring leakage. A combined leakage as

indicated by a one inch bubble in not less than three

seconds is permissible. Release the service brake

application.

4.

With tractor and trailer air brake system fully

charged, place the tractor protection control valve

in the "emergency" position or close the emergency

line cut-out cock on the tractor and uncouple the

trailer emergency line coupling. Note that trailer

brakes apply promptly. Check at the supply

(emergency) line coupling at the front of the trailer for

leakage. No leakage permitted. A leak detected at

the supply (emergency) line coupling would indicate

leaking check valve or piston O-Rings in the valve

Check at service line coupling at the front of the

trailer. A leak at the service line coupling would

indicate leaking relay piston O-Ring. Reconnect

service and emergency lines and recharge tractor

and trailer air brake system, noting that trailer

8-6