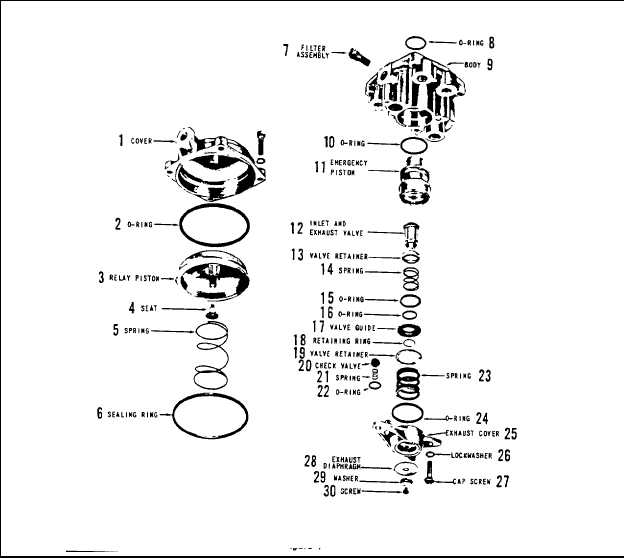

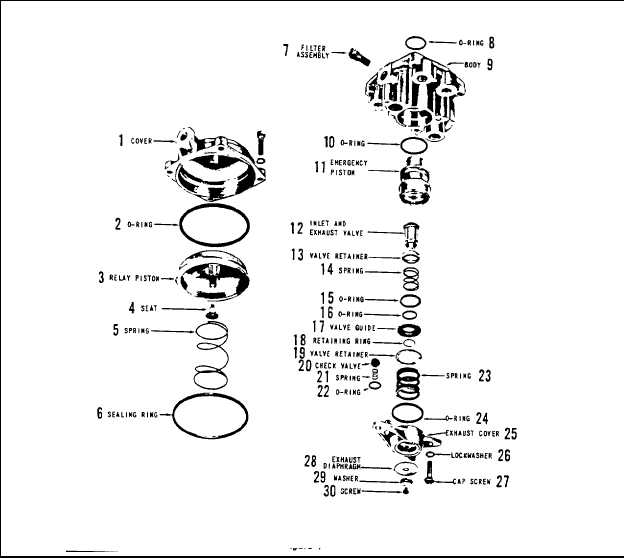

6.

Install emergency piston O-Ring (10).

7.

Install filter assembly (7) in emergency (supply)

port.

8.

Install seat (4) on piston.

9.

Install O-Ring (2) on piston.

10. Install O-Ring (8) in upper bore of body.

11. Install sealing ring (6) in groove of body.

12. Install relay piston (3) in cover. (Boss on cover

will fit bore in piston.)

13. If so equipped, install piston return spring (5)

14. Install cover to body, make certain cover is

in previously marked position. Torque cap

screws to approximately 100 inch pounds.

15. Install emergency piston and inlet/exhaust valve

insert in body.

16. Install O-Ring (24) in body.

17. Install spring (23) in body.

18. Install exhaust diaphragm (28), washer (29) and

screw (30).

19. Install small O-Ring (22) in exhaust cover.

20. Install check valve (20) and spring (21). Spring

will fit in groove in cover.

21. Install exhaust cover (25) install cap screws

and lockwashers, torque to approximately 100

inch pounds.

22. Check valve as outlined in "Operating and

Leakage" check sections before placing vehicle

in service.

Exploded View

Figure 4.

8-8