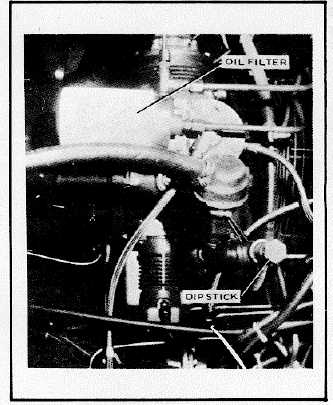

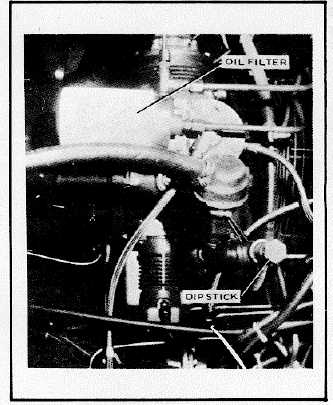

Figure 5-19. Compressor Oil Filter

b.

When oil flow stops, install drain plug. Service

compressor oil filter, refer to COMPRESSOR

OIL FILTER (Section V), at proper interval.

Service

compressor

air

filter,

refer

to

COMPRESSOR AIR FILTER (Section V), at

proper interval.

c.

Remove compressor oil level dipstick from

filler pipe. Fill compressor oil sump with four

quarts of clean lubricating oil (refer to Table 5-3).

When compressor oil filter is changed, fill sump

with five quarts of oil. Install dipstick.

d.

Remove container from beneath compressor

drain and discard old oil.

5-28. Compressor Oil Filter (Figure 5-19). To change

the compressor’s oil filter, proceed as follows:

a.

Turn filter

counterclockwise

using

a

strap

wrench.

b.

Wipe the contact surface of the new filter clean

of all dirt and coat the rubber gasket with clean

oil.

c.

Clean the mating surface of the adapter on the

compressor. To install filter, hand turn the new

filter clockwise until the gasket just contacts the

mounting bracket. Do not use a strap wrench to

install filter.

Figure 5-20. Priming Air Compressor Assembly Oil

Pump

d.

Hand turn the filter an additional half turn

clockwise.

5-29. Priming

Air Compressor Assembly Oil Pump.

(Figure 5-20).

To prime the air compressor assembly

oil pump, proceed as follows:

NOTE

After changing the oil filter or putting an

air compressor unit into service, which

has been idle or in storage for a

considerable length of time, it may be

necessary to prime the compressor

pump to obtain a correct air compressor

oil pressure indication.

a.

Disconnect oil filter-to-oil pump tube assembly (I)

at adapter (2) on oil filter mounting bracket (3).

b.

Raise oil filter-to-oil pump tube (I) slightly above

adapter (2).

c.

Using a pressure type oilier (4), containing

compressor lubricating oil as specified in Table

5-3, fill oil filter-to oil pump tube (I) until oil flows

from tube.

d.

Connect oil filter-to-oil pump tube (1) to adapter

(2).

5-17