Provide adequate ventilation when using

dry

cleaning

solvent

(Federal

Specification P-D- 680, Type 11). Avoid

prolonged

breathing

of

vapors

and

minimize skin contact.

c.

Wipe out cavity of cooling passages with a lint

free cloth dampened in solvent, per Federal

Specification P-D- 680, Type II. Allow to air dry.

d.

Install the cooling ducts for the engine cylinders

and blower assembly.

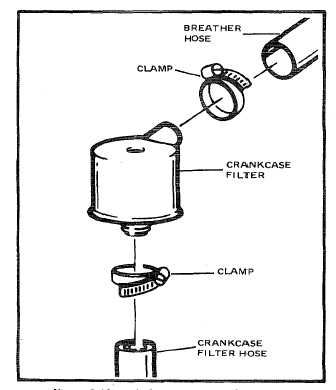

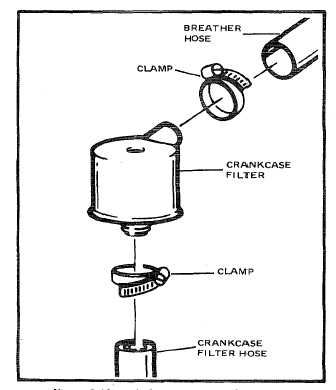

5-18. Air Compressor Crankcase Filter (Figure 5-12).

To clean air compressor crankcase filter, proceed as

follows:

a.

Unscrew two hose clamps. Disconnect breather

hose and crankcase filter hose from crankcase

filter. Remove filter.

Provide adequate ventilation when using

dry

cleaning

solvent

(Federal

Specification P-D- 680, Type II). Avoid

prolonged breathing of vapors’ and

minimize skin contact.

Figure 5-12. Air Compressor Crankcase Filter

b.

Soak filter in solvent, per Federal Specification

P-D- 680, Type II, to clean internal element of

sludge and blow-by material.

c.

After agitating filter in solvent, shake filter dry.

d.

Using hose clamps, attach filter to breather hose

and crankcase filter hose.

5-19. Engine Crankcase Breather Sieve (Figure 5-13).

To clean the engine’s crankcase breather sieve, proceed

as follows:

a.

Using a 13 mm deep socket, remove nut and

washer from stud.

b.

Remove breather cover and tube from stud.

c.

Remove gasket, spring, stroke limiter, valve

diaphragm, and valve plate from stud. Remove

intermediate ring gasket from crankcase.

d.

Using a 13 mm, deep socket, remove nut and

stud from crankcase.

e.

Remove sieve from crankcase.

Provide adequate ventilation when using

dry

cleaning

solvent

(Federal

Specification P-D- 680, Type II). Avoid

prolonged

breathing

of

vapors

and

minimize skin contact.

f.

Soak sieve in solvent, per Federal Specification

P-D-680, Type II, to clean sieve of slidge and

blow-by material.

g.

After agitating sieve in solvent, shake sieve dry.

Do not over tighten nut against sieve

screen.

h.

Using one nut and stud, assemble sieve to

crankcase.

i.

Place valve plate, valve diaphragm, stroke

limiter, and spring over stud.

j.

Assemble gasket and breather cover and tube to

stud using one flat washer and nut.

5-12