a.

Unscrew the filter bowl from the head. If

required, use a wrench on the square boss

located on the bottom of the filter bowl.

b.

Remove the element assembly from the filter

head, discard element and replace with an

AN6235-2A type element assembly.

Tighten the filter bowl in the head, hand

tight only. Sealing is accomplished by

the o-ring seal, not by tightening.

c.

Check o-ring and backup rings for deterioration,

cuts, or other damage. Replace as necessary.

d.

Make certain the new element assembly is

seated properly in the filter head and screw the

bowl in the filter head. Do not overtighten.

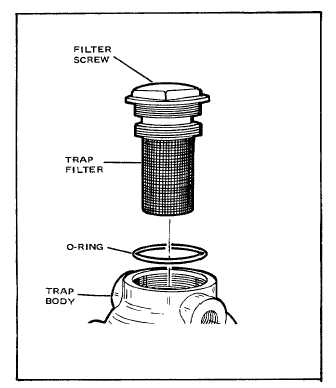

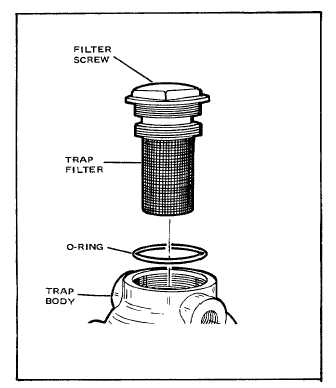

5-12. First, Second, and Third Stage Traps (Figure 5-8).

To inspect and clean the first, second, and third stage

trap filters, proceed as follows:

Figure 5-8. First. Second, and Third Stage Traps.

Make certain that all air pressure has

been relieved from the compressor air

supply

system

by

opening

the

mechanical filter drain valve, dehydrator

bleed valve, and service hose bleed

valve.

a.

With

compressor

stopped

and

unloaded,

unscrew and remove the trap filter assembly and

o-ring from the top of the trap body. Remove the

o-ring.

Provide adequate ventilation when using

dry

cleaning

solvent

(Federal

Specification P-D- 680, Type II). Avoid

prolonged

breathing

of

vapors

and

minimize skin contact.

b.

Wash filter screens thoroughly in solvent, per

Federal Specification P-D-680, Type II. Allow

filters to air dry.

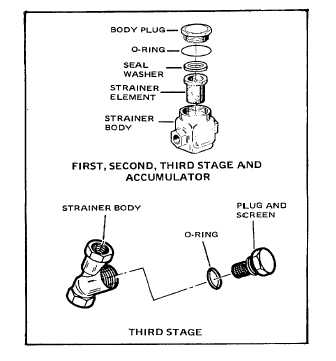

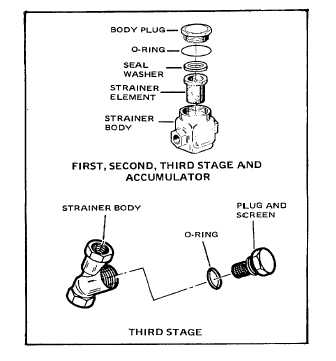

Figure 5-9. Line Strainers

5-9