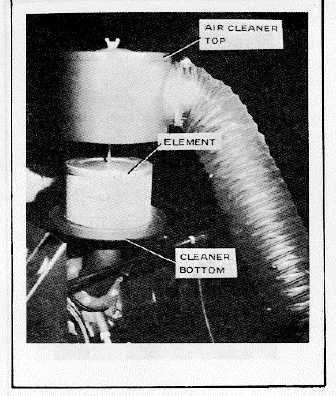

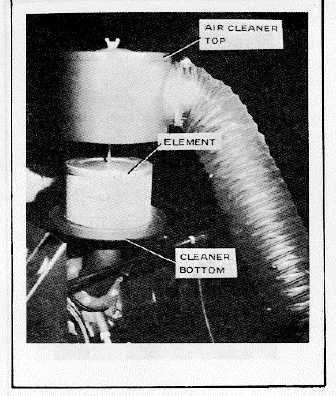

Figure 5-2. Air Compressor Air Filter

e.

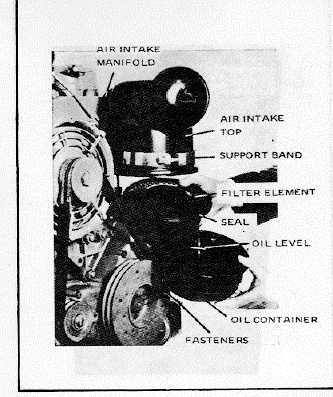

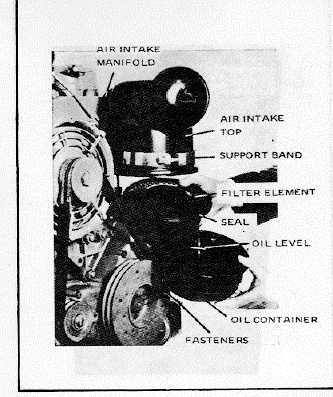

Care should be taken when either cleaning

or assembling oil pan so that the seal is not harmed.

f.

Clean mesh in filter using a hot water and

detergent solution per Federal Specification P-D-220.

Allow mesh to air dry.

g.

Fill oil container to mark with clean engine

oil. Refer to LUBRICATION (Section V) and Table 5-3.

Install oil container on air filter housing.

h.

Remove rain cap from air intake and clean

dirt from air intake tube. Replace rain cap.

5-7.

Dehydrators and Air Purification Cylinders. (See

Figure 5-4 and Figure 8-2). The cartridges and filter

elements shall be changed in accordance with the

number of recorded operating hours. (See Table 5-2.)

To change the cartridges on cylinders, proceed as

follows:

WARNING

Make certain that all air pressure has

been relieved from the compressor air

supply system by opening the SERVICE

HOSE

Figure 5-3. Engine Air Filter

BLEED VALVE, DEHYDRATOR BLEED

VALVE

and

MECHANICAL

FILTER

DRAIN VALVE.

a.

Using a strap wrench, unscrew cylinder

caps

from

either

dehydrators

or

air

purifications

cylinders.

CAUTION

Do

not

interchange

cartridges/filters

between

cylinders,

or

reuse

cartridges/filters.

b.

Remove

cartridges

from

cylinders,

thoroughly clean the inside of the cylinders with a lint free

cloth using hot water and detergent solution per Federal

Specification P-D-220. Allow cylinder to air dry.

c.

Examine o-rings in the cylinder caps and

replace if damaged. Use AN6227B-35 or AN6227B-36

o-rings.

d.

Remove

and

discard

cartridges

in

dehydrator cylinders.

f.

Place fresh type MA-2 cartridge in both

dehydrator cylinders (cylinders I and 2) (see Figure 5-4

and Figure 8-2).

5-5