compressor unit should load at a minimum pressure of

2,300 psig ( 1 5847 kPa). Air compressor unit should

unload at a maximum pressure of 3,300 ± 50 psig

(22,392 kPa). If air compressor loads or unloads at an

incorrect pressure, refer to PRESSURE SWITCH

ADJUSTMENT (Section V).

k.

Push ENGINE THROTTLE CONTROL to

the idle position. Disengage clutch by pulling CLUTCH

operating rod away from control panel.

l.

Allow engine to run without a load at a

maximum speed of 1,400 rpm (1,400 r/min) for

approximately five minutes.

m.

Push ENGINE TIHROTTLE CONTROL

completely in. Turn MASTER SWITCH 45° ccw.

n.

To drain the air from the air compressor

system, open the DEHYDRATOR BLEED VALVE,

mechanical filter drain valve (II), and service hose bleed

valve (13).

5-3.

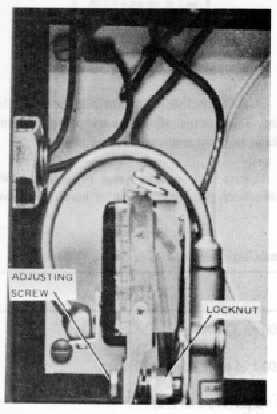

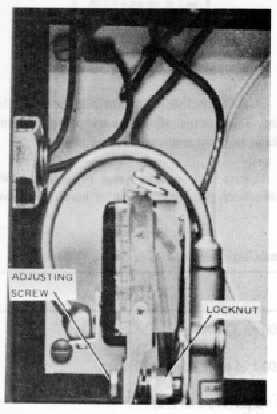

Pressure Switch Adjustment (Figure 5-1). The

pressure switch is located in the unloader control box

(Figure 1-1). Unfasten and raise cover of control box.

To adjust pressure switch actuating point, proceed as

follows:

Figure 5-1. Pressure Switch Adjustment

a.

Observe

compressor

pressure

gauge

indication when compressor unloads. The air

compressor unit should unload at 3300 ± 100 psi (22,757

± 689 kPa).

b.

Using an open end wrench, or offset

screwdriver, turn adjusting screw clockwise to decrease

switch actuating pressure and counterclockwise to

increase switch actuating, pressure.

c.

Observe service pressure gauge

(4)

indication. With air compressor unit operating under

normal conditions, compressor unit should load at a

minimum pressure of 3,000 psi (20,670 kPa). The air

compressor unit should unload at a maximum pressure

of 3300 psi ± 50 psi.

5-4.

INSPECTION

AND

PREVENTIVE

MAINTENANCE.

Preventive

maintenance

checks,

services,

and

inspection are listed in Table 5-2. Detailed procedures

are contained in following paragraphs. The table lists the

service time in intervals of operating hours. If a check,

service, or inspection procedure should be accomplished

at an interval other than operating hours, the time interval

is listed in the service column.

5-5.

Air Compressor Air Filter (Figure 5-2). The

compressor air cleaner is a dry, replaceable element

type. Service the air cleaner as follows:

a.

Unscrew the winged nut on the top

assembly. Remove the top cover and filter element.

b.

If inside of filter can is dirty, clean with lint

free cloth.

c.

Install cleaned or new element on filter can

base, install filter cover, with the air inlet hole pointing

away from the compressor. Screw wing nut down finger

tight.

5-6.

Engine Air Filter (Figure 5-3). The engine air

filter is an oil bath type. Service the air filter as follows:

a.

Remove supporting band front air cleaner.

b.

Unfasten and remove oil container from air

filter housing.

c.

If oil is dirty, dump oil and dirt from

container.

d.

Clean container with a lint-free cloth using a

hot

water

and

detergent

solution

per

Federal

Specification, P-D-220. Allow oil container to air dry.

5-2