f.

Repeat steps b through e for cylinder number

two.

g.

Attach cylinder head cover to cylinder head.

h.

Install glow plug in cylinder head cover.

i.

Reconnect negative battery cable to negative

terminal of battery.

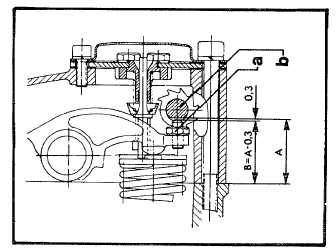

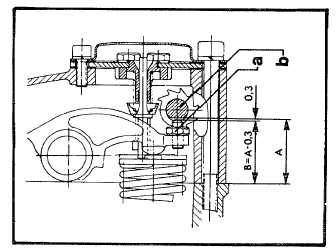

5-21. ENGINE COMPRESSION ADJUSTMENT (See

Figures 5-15, 16). To check the compression and to

adjust compression, proceed as follows:

a.

Turn flywheel in direction of rotation until

compression resistance is first noticed.

b.

Check and record measurement "A" (see figure

5-16).

In the decompressed position, the valve

must open just far enough so that the

engine can be turned over without

resistance. Do not allow the valve to

touch the piston.

c.

Loosen lock nut (a) and adjustment screw (6)

using a feeler gauge set at 0.012 inch (0.3 mm).

Using a pair of pliers, adjust screw.

d.

Tighten lock nut (a) while holding adjustment

screws (b) with pliers. Recheck for correct

clearance after lock nut (a) is tightened.

5-22. Fuel Injector Nozzle Replacement (Figure 5-17).

To replace the fuel injector nozzle, proceed as follows:

Figure 5-16. Engine Compression Adjustment

Tolerances

a.

Using a 12 mm wrench unscrew the banjo bolts

attaching the fuel leak-off lines to the injectors.

Remove fluid passage bolt, gaskets, and spacer

from injector and fuel leak-off hose.

b.

Disconnect fuel lines at fuel injectors. Remove

fuel injector from cylinder head.

c.

Remove two M8 nuts and lock washers from

injector clamp using a 13 mm wrench. Remove

fuel injector clamp.

d.

To disassemble fuel injector, unscrew nozzle

holder from retainer nut. Remove shims,

pressure spring, pressure spindle, intermediate

disc, and nozzle from nozzle holder.

e.

Replace nozzle with a new nozzle.

NOTE

Test repaired fuel injector in accordance

with instructions set forth in Section VI,

paragraph 6-39, Fuel Injector Assembly.

f.

Place new nozzle, intermediate disc, pressure

spindle, pressure spring, and shims in retainer

nut. Coat threads of nozzle holder with a light

coating of oil, per Military Specification MILL-

2104 or equivalent. Screw nozzle holder into

retainer nut. Tighten holder to 63 pounds-foot

(85Nm) torque.

Make

certain

washer

is

properly

positioned in cavity of cylinder head.

g.

Place assembled fuel injector in cavity of cylinder

head.

h.

Place clamp over injector.

i.

Attach clamp to cylinder head using two washers

and nuts.

j.

Connect fuel pressure lines to injector.

k.

Connect fuel leak-off hose to injector using

spacer, washers, and a fluid passage bolt.

l.

Repeat steps a through k for fuel injector

number two.

5-24. LUBRICATION INSTRUCTIONS. Points of

lubrication, type of lubricant, application, and time

interval are listed in Table 5-3. Detailed instructions are

as follows:

NOTE

So oil will flow more freely, drain oil from

the engine crankcase while the engine is

hot.

5-14