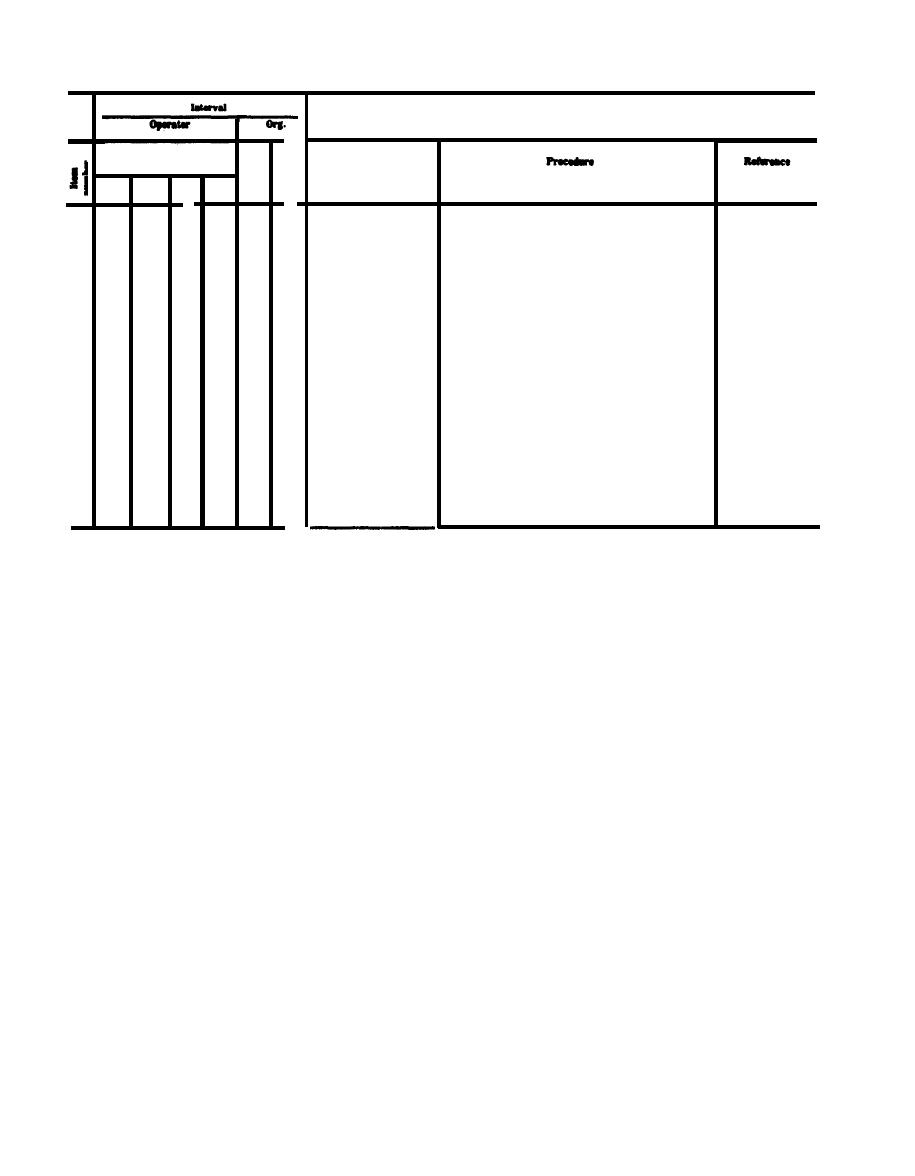

B- Before Operation

A- After Operation

M - Monthly

W- weekly

D- During Operation

Q-Quarterly

Items to be lnspected

Daily

M

Q

A

w

B

D

--

x

x

AIR RECEIVER:

Drain condensate. Tighten loose mounting and

1

connections.

x

x

x

LIGHTS

& Replace burned out lamps. Replace cracked

2

lenses.

x

AIR

PRESSURE Check for normal gage reading of 125-150 Ibs.

GAGE:

x

HYDRAULIC

Add oil as required. Refer to current L.O.

4

PUMPS:

x

x

Inspect for damage and loose mounting.

f) DYNAMOTOR-

5

WELDER:

x

WELDER IN-

Normal Readings; 240 volts. 50-60 cycles

6

STRUMENTS:

AC Voltmeter

Frequency Meter

Indicates applied load current not to ex-

DC Ammeter:

ceed 300 amps.

Terminal voltage.

DC Voltmeter

x

Add oil as indicated. Refer to current L.O.

7

DIPSTICK:

--

3-2