(2) Inspect for cracks, breaks, signs of leakage,

and other damage.

(3) Replace a defective side lifting hydraulic

pump.

d. Installation.

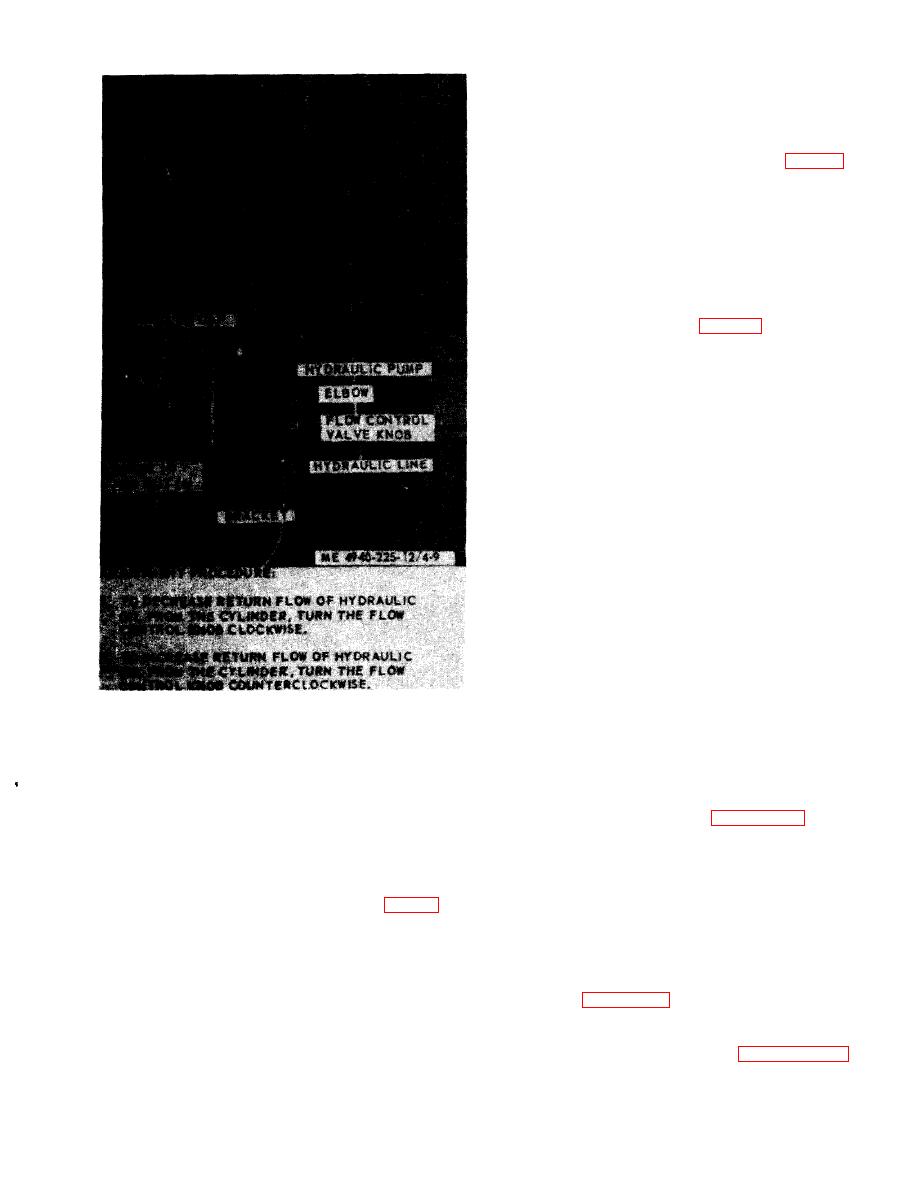

(1) Install the flow control valve in the elbow

and install the elbow in the cylinder pump (fig. 4-

9).

(2) Install the hydraulic pump in the bracket.

and secure with screws, nuts, and washers. Connect

line to flow control valve.

e. Bleeding Side Lifting Hydraulic System.

NOTE

See that all leaks are corrected before bleeding the

side lifting hydraulic system.

(1) Remove the filler cap (fig. 4-9) from the

top of the pump and add fluid as necessary in

accordance with the LO 5-4940-225-12. Install and

tighten filler cap.

(2) Pressurize the system and raise the side.

When the cylinder assembly reaches one-third its

extended position, any air in the system can be bled

by loosening the hydraulic line connection, at the

flow control valve, just enough that air in the line

can escape. When hydraulic fluid begins to appear,

tighten the connection. Refill the hydraulic pump

after bleeding and while side door is closed.

4-27. Side Lifting Cylinders and Hydraulic

Lines

a. General. A side lifting cylinder is located on

each side of the shop set body. The upper end of

each cylinder is attached to a rib in its respective

side door, The lower end of each is connected to a

removable bracket secured to the shop set floor.

Hydraulic oil flows into and out of the cylinders

through a flexible line connected at the bottom of

each cylinder.

b. Removal.

(1) Raise the side door on which the side lifting

cylinder is to be removed and secure in the raised

a. General. The side lifting hydraulic pumps are

position.

mounted on the front of the shop set body; one on

(2) Remove the side lifting cylinder and

each side. Each pump is manually operated by a

hydraulic lines as illustrated in figure 4-10.

handle stored on the front of the body adjacent to

c. Cleaning, Inspection, and Repair.

each pump. The pumps are secured to permanent

(1) Clean all parts with cleaning solvent and

mounting brackets welded to the shop set body.

dry thoroughly.

b. Removal.

(2) Inspect all parts for cracks, breaks, wear,

and other defects.

from the flow control valve.

(3) Replace a defective side lifting cylinder or

(2) Remove four screws, nuts and washers,

related parts and lines that cannot be repaired.

and remove the hydraulic pump from the bracket.

d. Installation.

(3) Remove the flow control valve from the

(1) Install the side lifting cylinder and lines as

elbow and remove the elbow from the hydraulic

illustrated in figure 4-10.

pump.

(2) Lower the side door.

c. Cleaning and Inspection.

(3) Bleed the side lifting cylinder and lifting

( 1 ) Clean external surface of the pump with a

door hydraulic system as described in paragraph 4-

cloth dampened in cleaning solvent and wipe dry.

22.